NTD spoke with Denis Gagnon, CEO of Belt Technologies, about manufacturing activity and material shortages.

Month: February 2022

Belt featured on World’s Greatest

[et_pb_section fb_built=”1″ _builder_version=”4.16″ _module_preset=”default” global_colors_info=”{}”][et_pb_row _builder_version=”4.16″ _module_preset=”default” global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.16″ _module_preset=”default” global_colors_info=”{}”][et_pb_text _builder_version=”4.27.4″ _module_preset=”default” hover_enabled=”0″ global_colors_info=”{}” sticky_enabled=”0″]

Our custom solutions caught the eye of Bloomberg’s “World’s Greatest” TV show. Click the link to view our segment.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

Lasercomb

CMS – CUTTING MILLING SYSTEM

- Combination device for cutting and milling

- Sample production and small series

- Simplest user interface

- Particularly stable due to one-piece substructure

- Highly efficient, even in a one-man operation

Lasercomb has decades of know-how and unique expert knowledge. For over 45 years, they have been developing innovative cutting and milling systems, and always rely on PureSteel® stainless steel belts from Belt Technologies to

drive their cutting units.

Whether paper, corrugated board, carbon fabric, acrylic or aluminum plates, there is hardly a material for which CMS does not have an outstanding solution. The use of PureSteel® steel belts allows the CMS to work extremely precisely

and with very tight tolerances. PureSteel® belts do not stretch like chain or fabric belts, and have a very high strength-to-weight ratio, which is why they are ideal for guiding along the X and Y axes.

PureSteel® steel strips allow the various cutting elements to run very smoothly, which further increases the reliability of the CMS. The PureSteel® steel belts also run quietly, and thus contribute to a better working environment.

The CMS can handle almost any cutting and milling task. Lasercomb’s engineers have equipped the CMS with everything necessary for consistent, excellent performance in many different application areas.

WHAT YOU CAN EXPECT:

- Ease of use

- High precision

- Low-maintenance operation due to the use of high-performance PureSteel® steel belts

- Flexible and customizable

LET’S SCHEDULE A TIME TO TALK ABOUT HOW PURESTEEL® BELTS

FROM BELT TECHNOLOGIES CAN HELP YOUR BUSINESS. REACH OUT TO US AT

BELTTECHNOLOGIES.COM/CONTACT

Custom Metal Belts Playing Key Role in Supporting High-Growth Industries

We are finding custom solutions to problems in a variety of industries with our PureSteel belts, bands, and drive tapes. Learn more about how we are supporting high-growth industries in this recent Design 2 Part article.

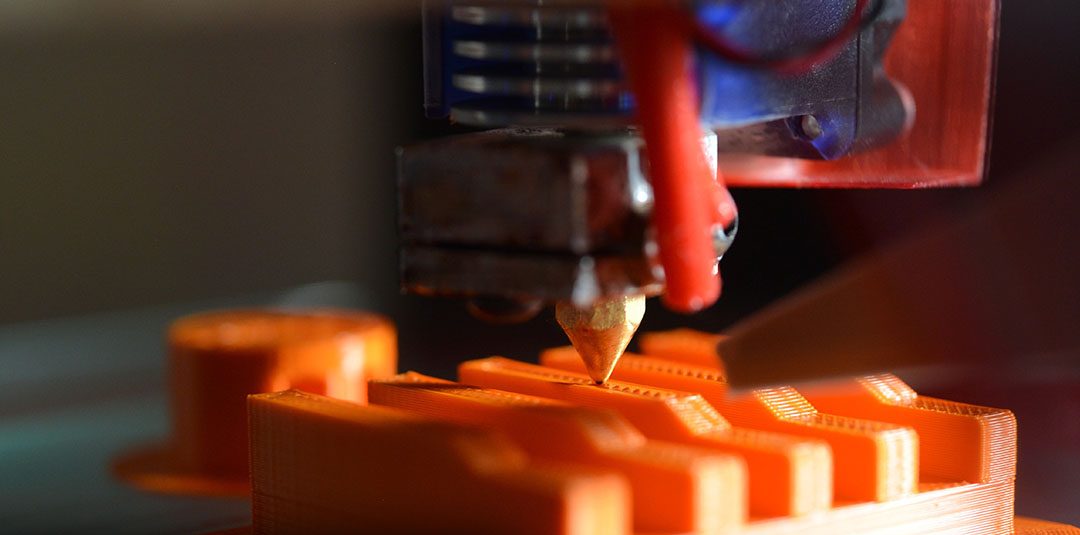

PureSteel®: The Continuous Conveying Solution for 3D Printing

While it has existed in some form for decades, 3D printing has emerged as an important and groundbreaking technology with near-limitless applications from manufacturing to medicine to aerospace and beyond. The process allows manufacturers to construct complex parts quickly and cost-effectively by creating a three-dimensional solid object from a digital file. In this blog, we’ll explain how our stainless steel belts are the perfect continuous conveying solution for 3D printing applications.

While it has existed in some form for decades, 3D printing has emerged as an important and groundbreaking technology with near-limitless applications from manufacturing to medicine to aerospace and beyond. The process allows manufacturers to construct complex parts quickly and cost-effectively by creating a three-dimensional solid object from a digital file. In this blog, we’ll explain how our stainless steel belts are the perfect continuous conveying solution for 3D printing applications.

Belt’s Role in the 3D Printing Process

A 3D printed object is created by using an additive process, which lays down successive sheets of material onto a surface, one layer at a time. One of the major aspects to consider in this process is the surface that the material is being printed on top of—is it movable? Impermeable? Smooth? PureSteel® belts, pulleys and drive tapes are excellent for additive manufacturing applications for these exact reasons.

The moveability of a surface provides two separate benefits. First, it allows multiple items to be printed simultaneously, without operator action to remove completed printed parts from the machine. It also allows for the printing of larger parts: a section can be printed and then indexed by the belt to print the next section until the part is completed. Both of these benefits can reduce labor expenses while increasing profit margins. Additionally, our PureSteel® belts will not stretch, warp or break, and the smooth, impermeable surface provides easy release of the extruded product. Unlike other belt options, seamless belts will not curl or warp the printed object.

The Creation of the Infinite Surface

The Belt team has worked on several impressive 3D printing projects in the past, including the development of the White Knight 3D printer by NAK 3D Designs, which is owned and operated by Karl Brown. After developing a personal interest in 3D printing, Karl strove to create an infinite printing surface for seamlessly printing large objects, something not previously possible. After being told by several 3D printing belt specialists that fulfilling the specifications for his design was not possible, he contacted Belt Technologies.

As fellow 3D printing enthusiasts, our team provided Karl with engineering and design feedback to determine the appropriate thickness for the size of the belt to ensure smooth, long-lasting operation. The endless belt, combined with linear rails and several additional top-of-the-line pieces enables the White Knight 3D printer to do what no one else can: print an 8-foot-long sword in one complete piece.

How Can We Help You?

The team at Belt Technologies is thrilled to see the success of Karl’s design—can we do the same for you? We’ll work with your design and engineering teams to ensure your 3D printer components not only achieve optimal results but also maximize the lifespan of your equipment. Contact us today to learn more about our PureSteel® 3D printer drive tape, timing tape and pulley manufacturing capabilities