It’s impossible to overstate the importance of sterilized equipment in a medical setting. Surgical instruments such as scalpels, forceps or scissors need to be regularly sterilized to protect patients from infection. In this regard, surgical technologists are unsung heroes—responsible for preparing operating rooms, sterilizing equipment and helping surgeons and patients before, during and after procedures.

We want to recognize this work during Surgical Technologists Week, which is observed each year during the third week of September. It’s a perfect time not only to highlight the importance of these workers, but to demonstrate Belt Technologies’ own role in supporting sterilized equipment production.

The Sterilization Process

To put it simply, sterilization is the process of making something free from bacteria or other living organisms. Surgical technologists can accomplish this in a variety of ways including the use of steam, dry heat, radiation, ethylene oxide gas or other methods. No matter the technique, these workers provide the medical cleaning and disinfecting measures needed to keep every person in a given facility safe. Without them, doctors, surgeons, nurses and others wouldn’t be able to safely perform their critical functions.

But what keeps these instruments hygienic before they can even make it to the surgery center? They need to be produced in a cleanroom environment, which means the surfaces that these instruments come into contact with during their creation also need to be hygienic. Stainless steel is the ideal material for this purpose, as it is known for its smooth and impermeable surface that does not hang on to microbes and bacteria.

The Sterile Benefits of Stainless Steel

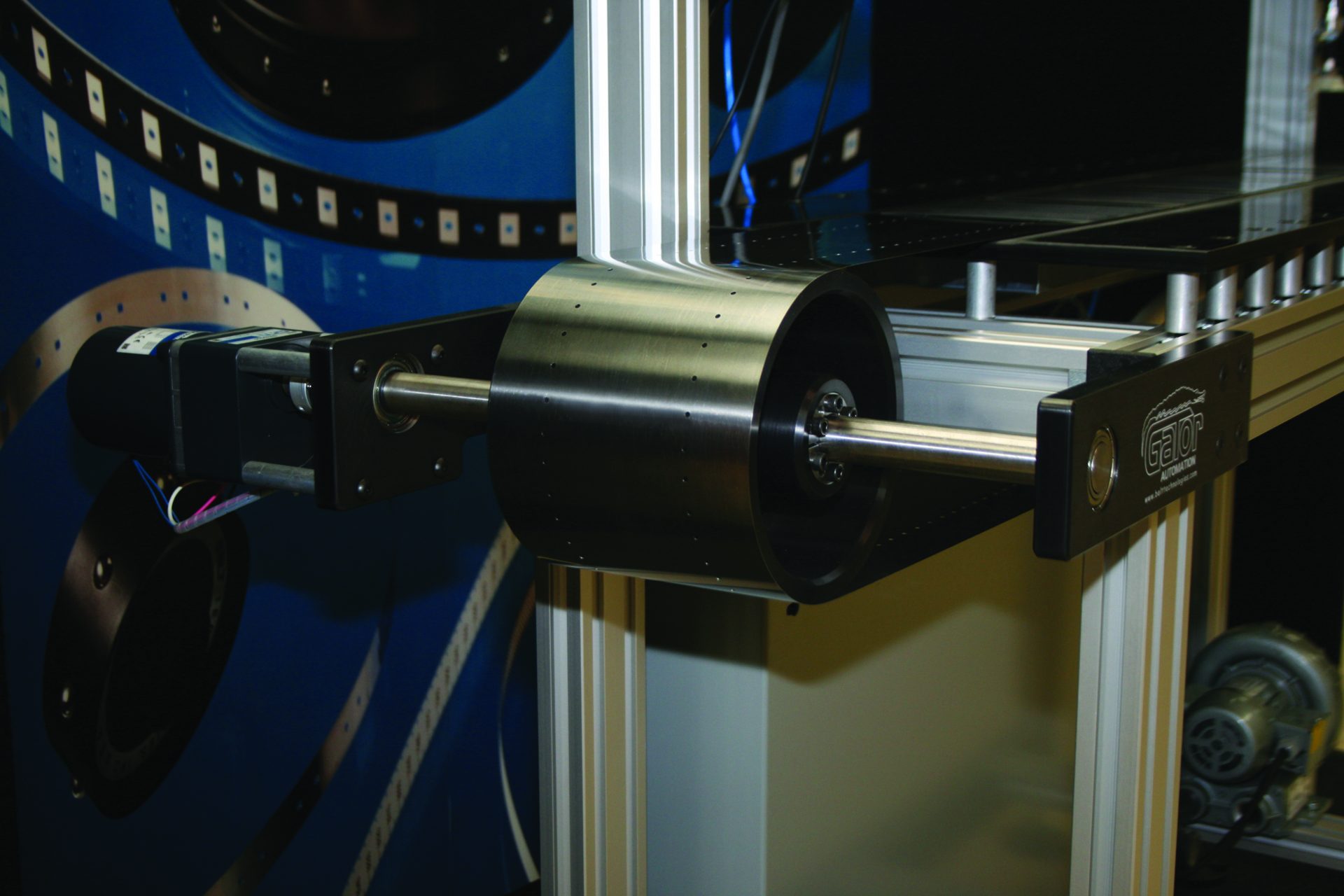

Compared to other belt materials such as flat neoprene or HTD, our PureSteel® stainless steel belts do not require dust-generating lubricant that could introduce foreign substances into cleanroom environments. Not only is stainless steel cleaner than other conveying materials to begin with, but it’s easier to keep that way—which is just as important. Stainless steel’s corrosion resistance allows it to be sanitized by high-pressure steam, high-pressure wash or chemical cleaning. The metal belt sterilization process can be performed in an autoclave; so, unlike materials that call for the belt to be removed from the conveyor for regular cleaning (which interrupts production), our belts can be cleaned in place.

Ready to Learn More?

Combined with a protective chromium oxide surface layer, our belts provide the longest-lasting and most hygienic surface for transporting surgical instruments during production. If you’re interested in learning more about how our products can help you, we’d welcome the opportunity to speak with you. Contact us today to learn more about how we can implement our belts in your facility.