Multilayered PureSteel® drive tapes prove essential in groundbreaking robotic surgery technology.

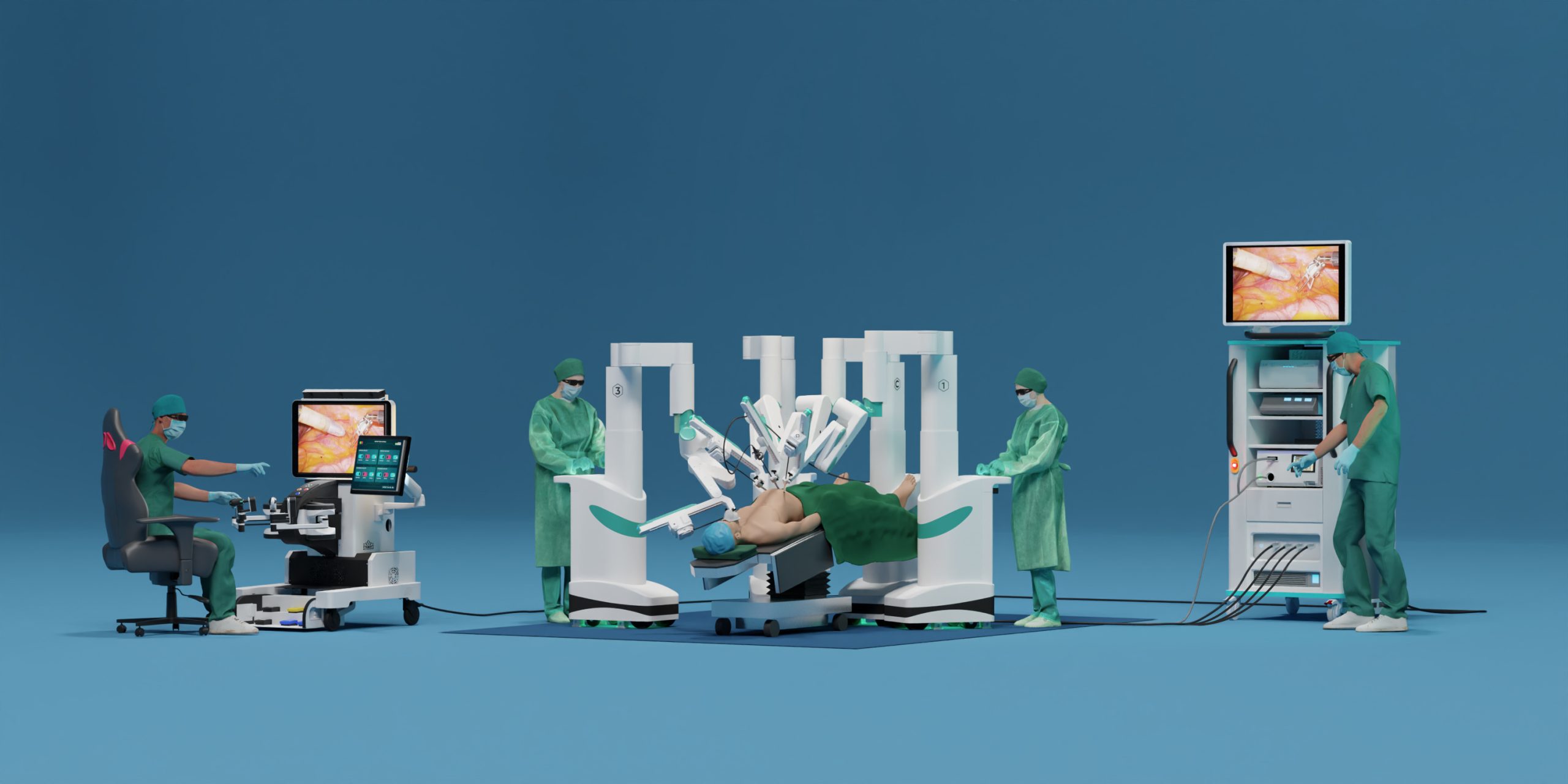

Robot-assisted surgery is transforming the medical field, allowing doctors to regularly perform complex procedures with unparalleled precision and control. In addition to being more accurate and less invasive, this technology allows top doctors in major metropolitan areas to perform surgeries at a distance, providing top-quality care to patients outside these areas who wouldn’t normally have access. Presently, there is one major hurdle toward widespread integration: cost. One company in India is trying to change that by developing new, technologically advanced yet cost-effective surgical systems that would benefit patients around the world. Discover why they chose Belt Technologies as a partner for this undertaking.

The Customer

A major medical equipment manufacturer based in northern India is revolutionizing robotic surgery with a solution that is affordable and accessible to underserved markets. The company has been operating in the field of medical robotic technology for the past decade with the ultimate goal of improving the quality of medical services for patients all over the world. Their surgical robotic system is improving access to surgery and health care for many who might not be able to receive it.

The Challenge

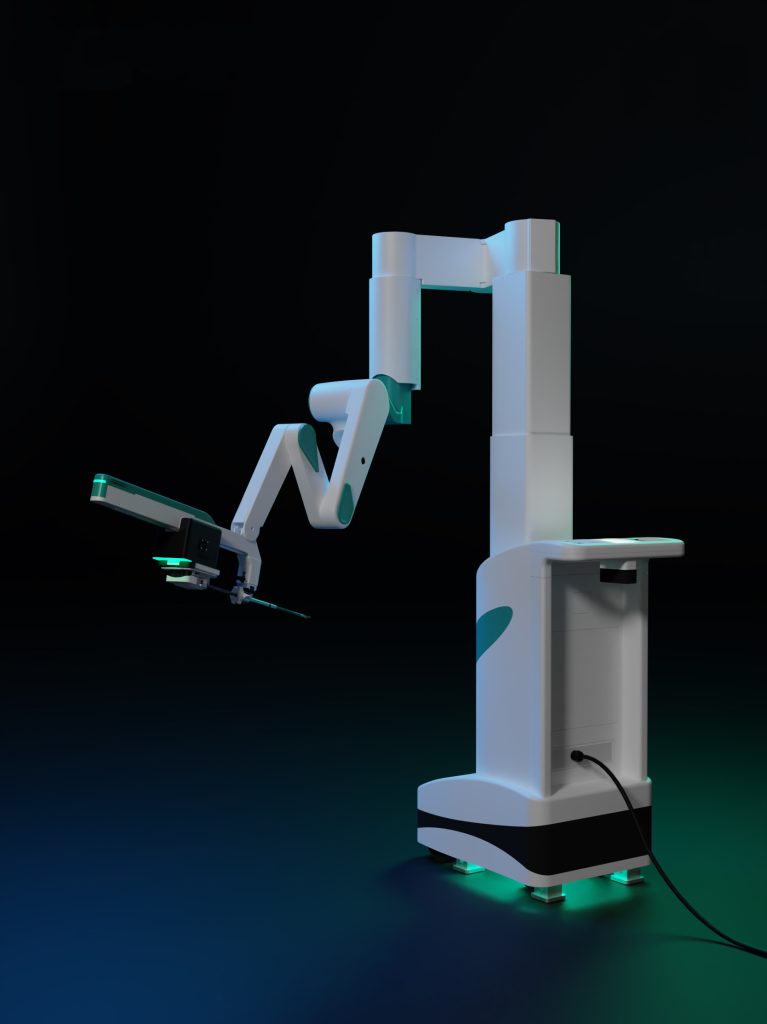

The system features a modular design of up to five robotic arms on individual motorized carts, allowing them to be placed anywhere throughout an operating room. Depending on the procedure, medical professionals use between three and five of the arms through a central Surgeon Command Center that includes a high-definition monitor and ergonomically designed hand controls.

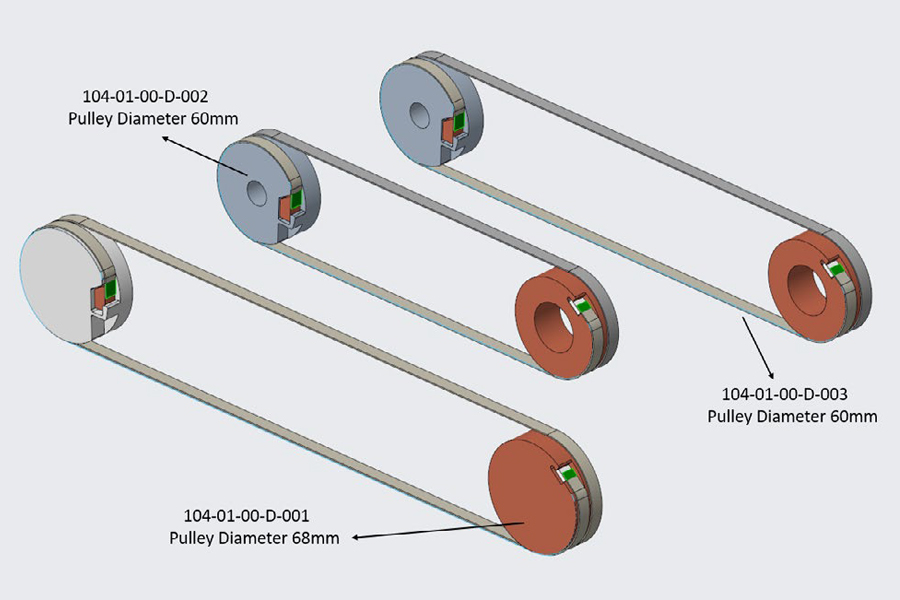

Each of the system’s five arms contains three joints. The individual joints are made up of two pulleys and two separate drive tapes for a total of up to 30 belts per system. These robotic arms must operate in conjunction with one another in a very confined space while holding small instruments. For this reason, the pulleys included in the system have to be as small as possible. Additionally, due to the delicate nature of surgery, the motion of these robots has to be entirely jerk-free with zero backlash.

The Solution

The biggest constraint our engineers encountered for this system was the need to decrease the size of the pulleys while maintaining the relative strength of a thicker metal drive tape. As a general rule of thumb, the thicker the belt, the larger the pulley needs to be to ease the bending stresses on the belt. Our solution was to incorporate two PureSteel® drive tapes, each with six layers of 0.127 mm thick stainless steel, stacked on top of one another and precision welded to form one uniform body. This multilayered belt configuration allows for a reduced pulley diameter while also allowing the system to carry heavy working loads due to the design’s increased cross-sectional area.

The pulleys are designed to only rotate 180 degrees, which means there is zero risk for quick, jerky motions. The two drive tapes work in tandem, with one propelling forward and the other driving the reverse motion. Given the inelasticity of steel, this design handles rapid acceleration and reversing without inducing any backlash.

The Results

The customer is now producing these systems at a fraction of their competitors’ cost.

In January 2023, the first thoracic surgery was performed with one of the systems. The procedure was a great success, and it’s not the only one; that first system has already completed more than a hundred successful surgeries since it was clinically implemented in December 2022.

Due in large part to these recent successes, our partnership has spurred mutual growth for both the customer and Belt Technologies. The company currently has orders for three dozen more robots over the next year, with planned yearly production increases for the foreseeable future.

The Company: A major medical equipment manufacturer based in northern India is revolutionizing robotic surgery with a solution that is affordable and accessible to underserved markets.

The Challenge: The customer needed to incorporate belts and pulleys in their system’s robotic arms. Due to the highly delicate nature of the surgery, the solution needed to be small and strong with zero risk of backlash.

The Solution: Our team incorporated a multilayered PureSteel® drive tape solution with six individual layers stacked on top of one another and precision welded to form one uniform body, reducing pulley diameter while increasing strength.

The Results: The customer’s system has facilitated more than a hundred successful surgeries and they have orders for more than three dozen robots, with planned production increases.