Vacuum conveyors are a pivotal technology for industrial automation and material handling, providing a level of precision, cleanliness and efficiency demanded by industries from pharmaceutical to food processing and electronics manufacturing.

Vacuum conveyors are a pivotal technology for industrial automation and material handling, providing a level of precision, cleanliness and efficiency demanded by industries from pharmaceutical to food processing and electronics manufacturing.

What is a Vacuum Conveyor?

A vacuum conveyor is a type of pneumatic conveying system that employs suction to move materials through an enclosed pipeline. By creating a pressure differential, materials are gently pulled from one location to another, ensuring a dust-free and hygienic transfer process. This method is particularly beneficial when handling fine powders, granules, and other dry materials. The core components of a vacuum conveyor system include:

- Vacuum Pump: Generates the necessary negative pressure to initiate material movement

- Conveying Line: An enclosed pipeline through which materials are transported

- Vacuum Receiver: Separates the conveyed material from the air stream before discharge

Vacuum conveyor systems are closed systems, ensuring material integrity and enhancing workplace safety by preventing dust emissions and potential contamination.

Benefits For Applications Across Industries

Vacuum conveyors help maintain a controlled environment, making them essential in processes demanding product purity and precision. They find applications across industries, including:

- Pharmaceuticals: For transferring active ingredients and excipients without contamination

- Food Processing: Ensuring hygienic movement of food ingredients

- Chemical Industry: Safely handling reactive or hazardous substances

- Electronics: Transporting delicate components in cleanroom environments

- Pick and place equipment

Steel Belts Enhance Vacuum Conveyor Performance with Precise, Smooth Motion

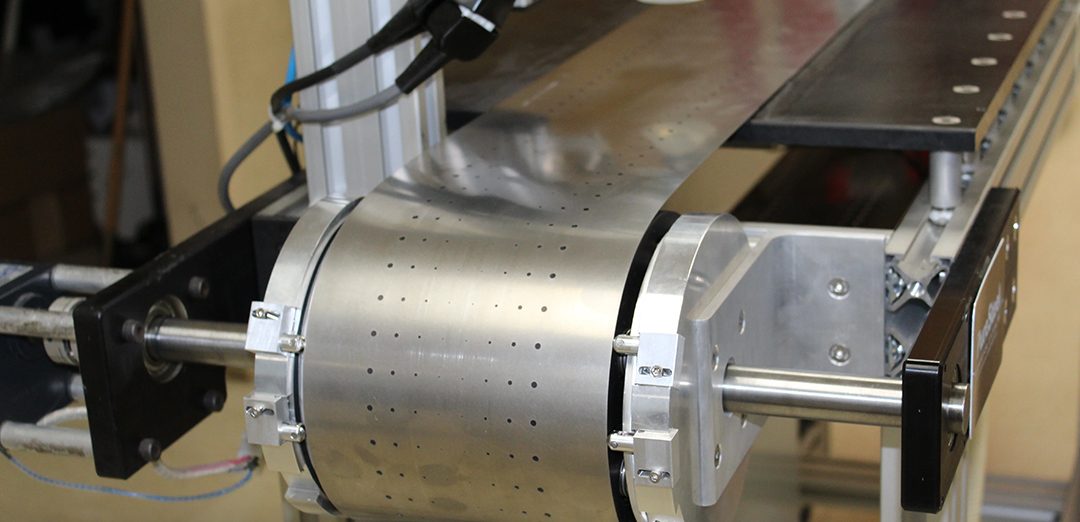

PureSteel® perforated metal belts are flat, endless metal conveyor belts manufactured with precision perforations, allowing for the passage of air drawn through grooves in the vacuum plenum of the conveyor to create a suction effect that holds flat product materials to the belt surface. This allows for a level of precision and accuracy unattainable with traditional systems.

Stainless steel belts provide:

- Precision Perforation: Our PureSteel® stainless steel conveyor belts are designed and manufactured based on the specific needs and specifications of our customers. A wide variety of different perforation patterns and sizes are possible, and our engineers will provide design feedback and technical support to ensure maximum efficiency. We use a variety of perforation methods based on the dimensions of the belt and the operational requirements of the vacuum conveyor system including: high-impact mechanical punching, chemical etching and laser cutting

- Material Integrity: Constructed from high-grade stainless steel, PureSteel® belts resist extreme temperatures, corrosion and wear. Their durability ensures longevity and reduces maintenance downtime. Steel is also ideal in applications involving elevation change and temperature fluctuations.

- Cleanroom Compatibility: Because PureSteel® stainless steel belts do not generate particulates, manufacturers can increase product throughput with less downtime spent cleaning or removing debris buildup.

- Smooth Motion Control: The inherent strength and stability of stainless steel provide precise, smooth motion—essential for applications requiring exact material placement.

Coatings and surface treatments for perforated metal conveyor belts are also available; our engineers will help you determine the right coating and PureSteel® product requirements for your system.

Vacuum Conveyor Belt Engineering

Engineers at Belt Technologies have the knowledge and experience to design and fabricate complete vacuum metal conveyor belt systems based on your specifications and product requirements and built to withstand even the most demanding production environments.

Interested in learning more about how PureSteel® can help optimize your vacuum conveyor system? Reach out to our team with questions.

Robotic automation

Robotic automation