Belt Technologies established the flat belt tracking design called the Independently Steerable Pulley, or ISP. This system improves belt alignment and tracking in various conveyor applications, including:

- Two-pulley conveyor systems in which the ISP is the idler or driven pulley

- Systems with multiple idler pulleys on a common shaft

- Conveyor setups with serpentine or complex belt paths

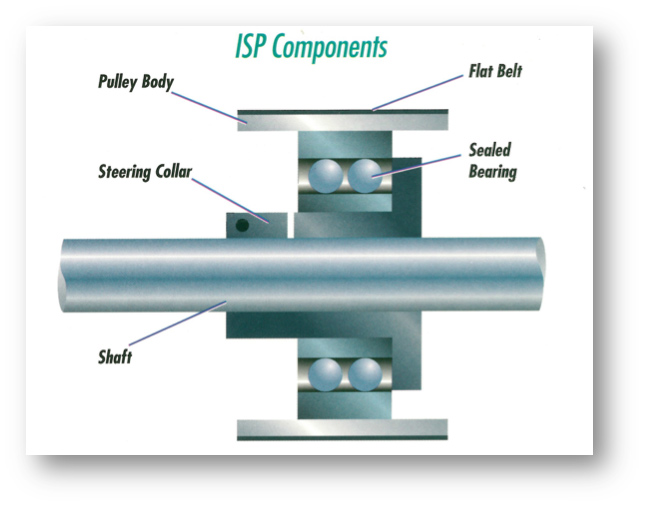

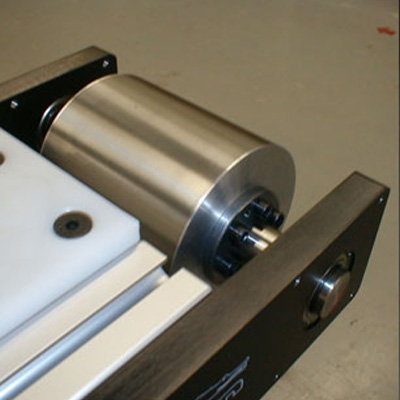

Rather than moving the pulley shaft left/right or up/down by pillow block adjustment, our PureSteel® ISP fits a steering collar and sealed bearing assembly to the body of the pulley. As the collar is rotated, the angle created by the two axes not being parallel creates uneven tension forces across the belt width, resulting in the belt moving from one side to the other.

The PureSteel® Independently Steerable Pulley (ISP) is exclusively available from Belt Technologies. It provides a simple method of steering flat metal belts. Users may combine ISP steering with the traditional belt tracking designs of flanging, and timing elements to create a simplistic belt tracking system which efficiently and precisely steers the belt to specified tracking parameters.

See All PulleysUnique Characteristics and Advantages of the ISP

Flat belts are tracked quickly by rotating the steering collar

- ISP designs minimize downtime when replacing belts on production machinery

- An ISP system is easy to use and requires no special tools or training

- The ISP simplifies the design and assembly of conveyor systems using flat belts

Existing idler pulleys can normally be retrofitted to an ISP without major system modifications

- No maintenance is required once the belt tracking parameters have been established

- An ISP prolongs belt life by minimizing side loading when using flanges and timing pulleys

Installation and Use

The PureSteel® ISP is mounted to the system frame using pillow blocks. A clamp is used to prevent the shaft from turning.

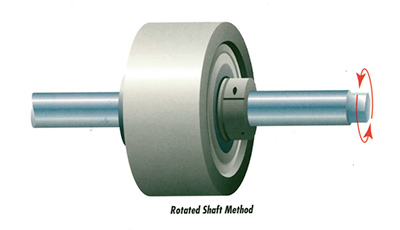

Rotated Shaft Method for Flat Belt Tracking

- Used with systems having a single pulley on the shaft

- ALWAYS used when the pulley body is a capped tube design

- NEVER used when multiple pulleys are on a common shaft

- Selectively applied when the ISP functions as a steering roll in a multi-pulley system

To put into use, secure the ISP to the shaft using the split collar and locking screw built into the ISP. Rotate the shaft and collar as a unit. When the desired tracking characteristics are obtained, lock the shaft in place by securing the shaft clamp. The pulley body will now rotate about the bearing built into the ISP assembly. This method allows the belt to be tracked while running under tension.

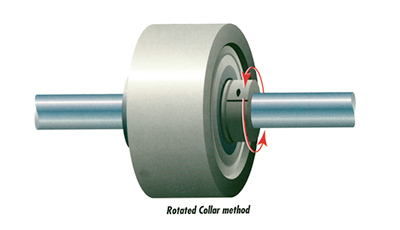

Rotated Collar Method of ISP Flat Belt Tracking

- Used to individually adjust each belt/pulley combination when there are multiple pulleys on a common shaft

- Used when systems have a cantilevered shafting typical of serpentine and other complex belt path systems. It is recommended that these adjustments be made with the belt moving slowly until the desired tracking characteristics are obtained.

To put into use, fix the shaft via the shaft clamp, loosen the locking screw of the steering collar, and rotate the steering collar about the shaft. When the desired belt tracking characteristics are obtained, secure the locking screw.

Which Design Is Right for You?

There are many applications for this new product, so Belt Technologies designs and manufactures independently steerable pulleys to suit your needs.

PureSteel™ System Configuration 1

- The ISP is a friction drive pulley. Teflon® flanges are attached to the pulley body to establish a lateral constraint. The steering feature of the ISP is used to set one edge of the belt against the flange with minimal side-loading to the belt.

- Tracking accuracy is 0.030″ (0.762 mm) or better.

PureSteel™ System Configuration 2

- The ISP is a friction drive pulley. The teeth of the drive pulley and the perforations of the belt establish a lateral constraint. The steering feature of the ISP is used to minimize side-loading of the belt perforations.

- Tracking accuracy is between 0.008″ (0.203 mm) and 0.015″ (0.381 mm) for metal belt systems.

OR

- The ISP is a timing pulley. The teeth of the ISP and the perforations of the belt are used for precise tracking control of the belt with the steering feature of the ISP used to minimize side loading of belt perforations.

- Again, tracking accuracy is 0.008″ (0.203 mm) to 0.015″ (0.381 mm) for metal belts.

Although it is generally not recommended to have timing elements in both the drive and driven pulleys, this design can be used selectively on metal belt systems with long center distances between pulleys and in applications where particulate accumulation on the surface of the pulley continuously changes the tracking characteristic of the belt.

Belt Technologies—Independently Steerable Pulleys

Interested in Learning More? Contact us today to learn how an ISP can transform your conveyor system’s performance.

Explore our PureSteel® Pulleys:

TruPace™ Pulley

See TruPace™ Pulleys

TruTrack™ Pulley

See TruTrack™ Pulley

Friction Drive Pulley

See Friction Drive Pulley