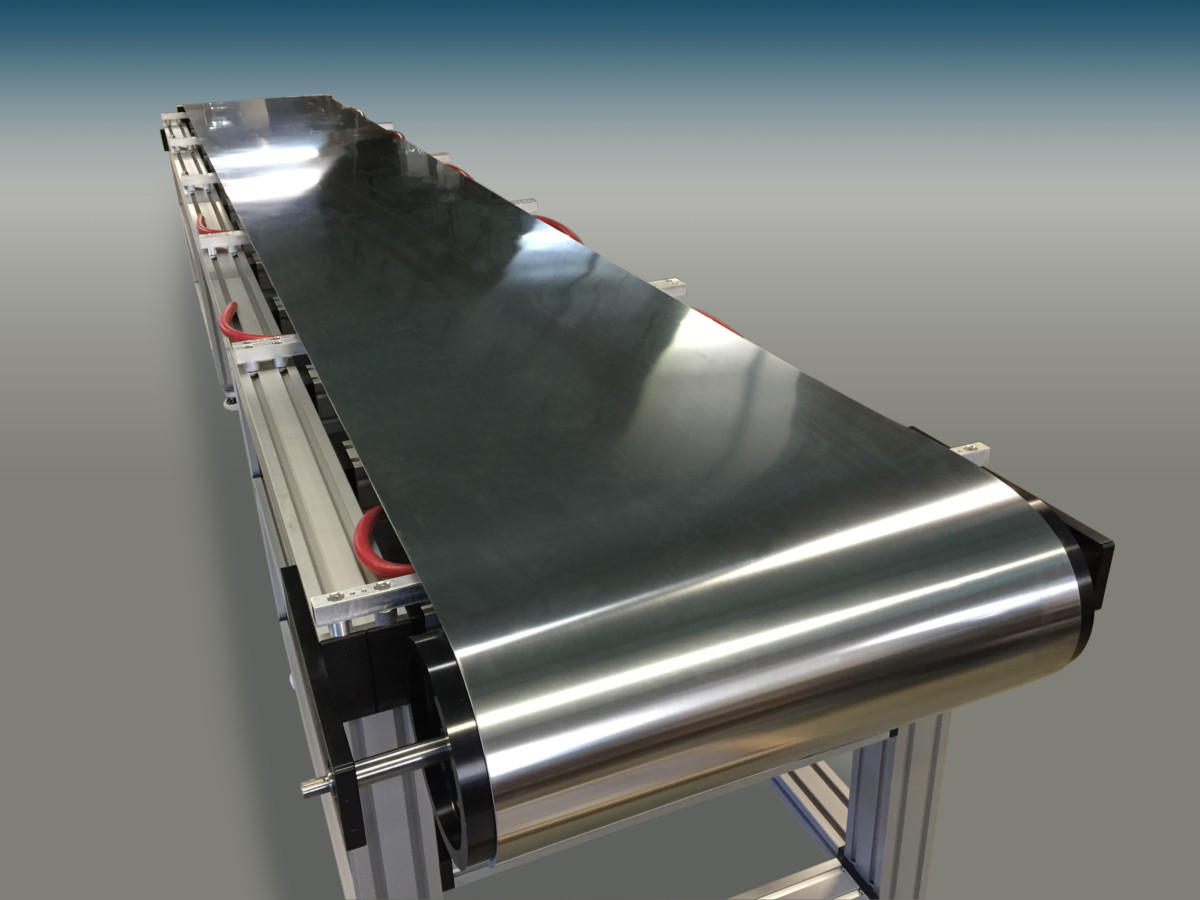

Steel Belt with Attachment Integration

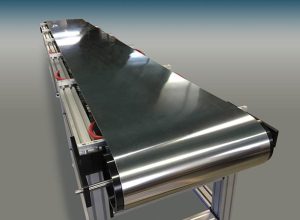

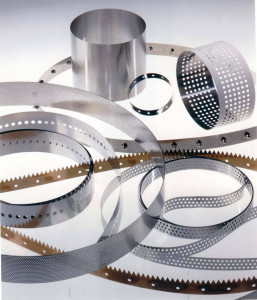

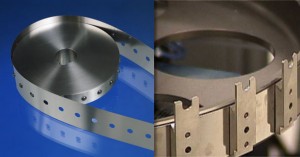

A vertical conveyor is a conveyor whose pulley rotational axes are perpendicular to the floor. This allows processes to be performed on both sides of the conveyor simultaneously, thus reducing the overall center to center distance between pulleys and overall footprint. The steel belting can be customized with patterns to hold tooling for most any automated assembly operation. Belt Technologies can engineer and manufacture PureSteel® stainless steel belts to your specific application and assembly a full custom vertical conveyor system to meet your requirements.

Benefits of Vertical Conveyor Belts

Vertical conveyors are used in automation applications to assemble products with a minimal footprint, increasing efficiency of production lines. Their benefits include:

- Processes can be performed on both sides of the conveyor

- They have a smaller overall footprint

- Surfaces are less likely to accumulate debris

- They are easy to clean

- They are resistant to bacterial adhesion

Vertical Conveyor Belt Applications

Applications of vertical conveyors include:

- Medical device production and processing

- Plating and coating products

- Material lift (raising and lowering products)

- General automated assembly

Benefits of Stainless Steel Vertical Conveyor Belt Systems

In addition to the opportunities offered by vertical belt positioning, benefits of PureSteel® stainless steel conveyor belts include:

- No need for lubricants

- Customizable with a wide variety of attachments and perforations

- High resistance to chemical corrosion

- High resistance to high or low temperatures

- Surface coatings and treatments to optimize product handling

- Sanitary and will not generate any particulates

Engineering Your Vertical Conveyor System

For the vertical conveyor to operate successfully, proper design of the methods of tracking and tensioning has to be considered. Due to gravity, the belt will want to track downward. Flanging the pulleys helps stabilize the belt and allows it to track true. Over tensioning the belt is a concern because the belt does not remain vertical and parallel to the shaft axis due to gravity. One way to improve its vertical position is to increase tension, which generally reduces belt life. A more straightforward approach is to either guide or trap the belt edges or guide or trap the tooling affixed to the belt. This ensures the belt is parallel to the rotating axis and allows for lower tension, thereby prolonging belt life.

We specialize in helping companies build and customize stainless steel conveyors. Our engineers have the knowledge and experience to effectively work with your design team to optimize your PureSteel® conveyor system and ensure you achieve the maximum lifespan and product throughput for your equipment.

Contact Belt Technologies today to speak with one of our engineers about your specific system application.