Improve Tube Seal Quality

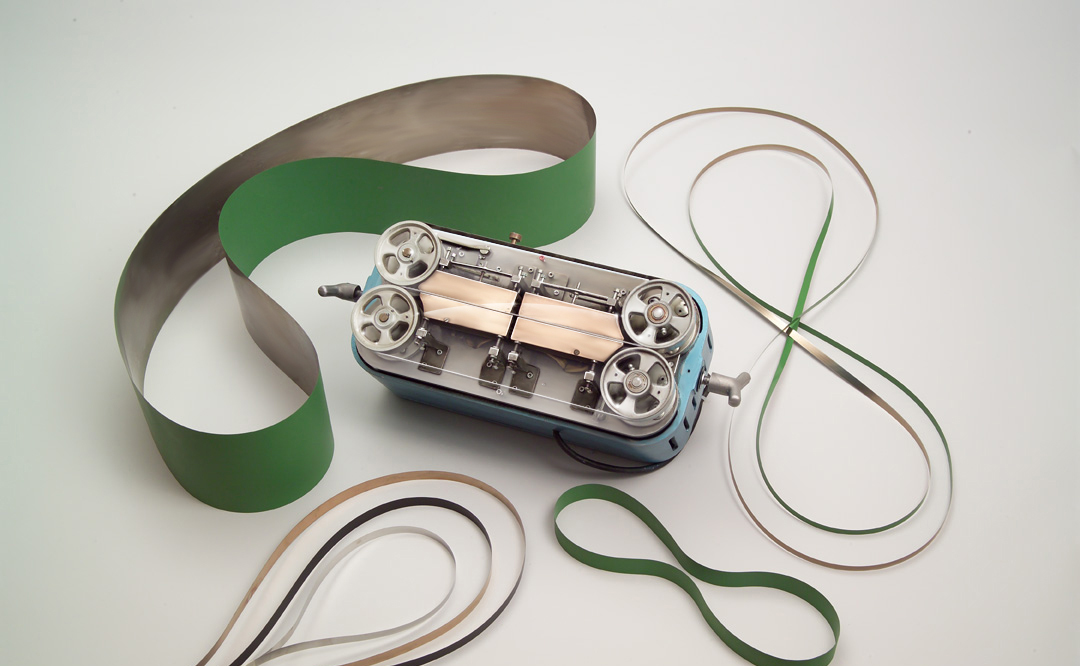

Heat-sealing belts are used to create the overlap joint for tube manufacturing. This belt design is capable of heat sealing both HDPE plastic and plastic-aluminum laminates under the high temperatures and pressures of the process.

Heat Sealing Applications

Continuous heat sealing belts and bands are used throughout the packaging industry to carry out the following applications:

- Flexible packaging (bag sealer, pouches, etc.)

- Food processing

- Pharmaceutical processing

- Sterile packaging for single-use medical devices

- Vacuum sealing

- Laminate tube sealing

Benefits of Stainless Steel Belts For Heat Sealing

Our PureSteel® stainless steel heat sealing bands are ideal for mid- to high-volume production and offer the following benefits to improve seal quality:

- Resistant to impact and corrosion damage

- • Perform well in high temperatures and pressures

- Do not require lubrication

- Do not generate particulates

- Do not build up static electricity

Additional Coating Options Available

Teflon™ coating can increase the release properties and durability of heat sealing bands.

Contact the experts at Belt Technologies today and find out more about our PureSteel® stainless steel heat sealing belts.