When precision, cleanliness and durability are non-negotiable, manufacturers turn to Belt Technologies, Inc. For over 50 years, we’ve engineered and manufactured PureSteel® stainless steel metal belts and conveyor systems for some of the most challenging industrial applications in the world, including demanding automation environments. Here’s a closer look at our proven manufacturing process and what sets us apart.

When precision, cleanliness and durability are non-negotiable, manufacturers turn to Belt Technologies, Inc. For over 50 years, we’ve engineered and manufactured PureSteel® stainless steel metal belts and conveyor systems for some of the most challenging industrial applications in the world, including demanding automation environments. Here’s a closer look at our proven manufacturing process and what sets us apart.

From Concept to Custom Solution: Collaborative Design

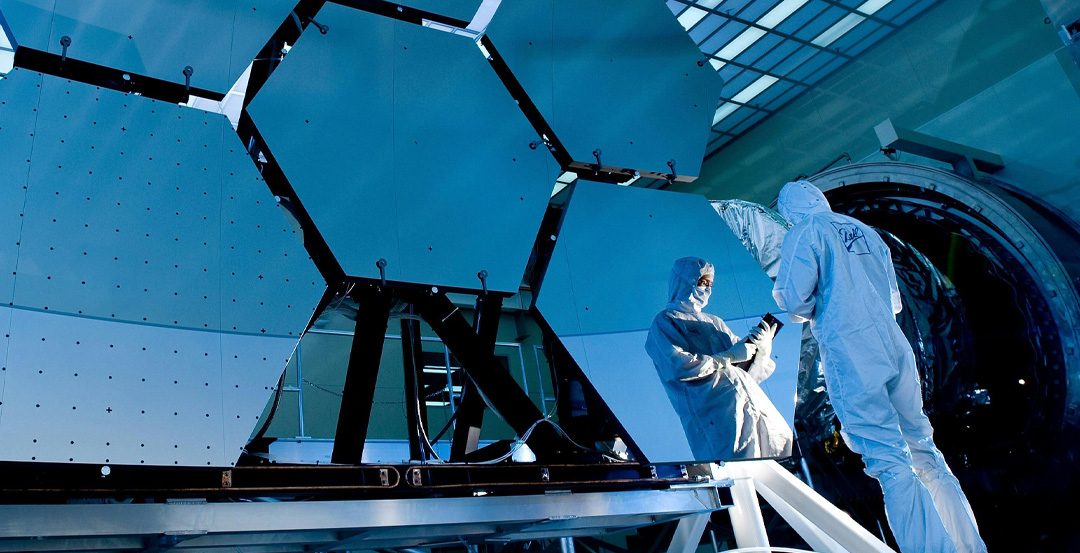

Every project begins with collaboration. Our experienced sales engineers work directly with customers to understand their unique application requirements. Whether it’s precise motion control in semiconductor fabrication or cleanroom compliance in medical device manufacturing, our team listens first. We take all details into account—dimensional tolerances, environmental conditions, throughput needs and integration requirements—to engineer a belt system that solves specific challenges.

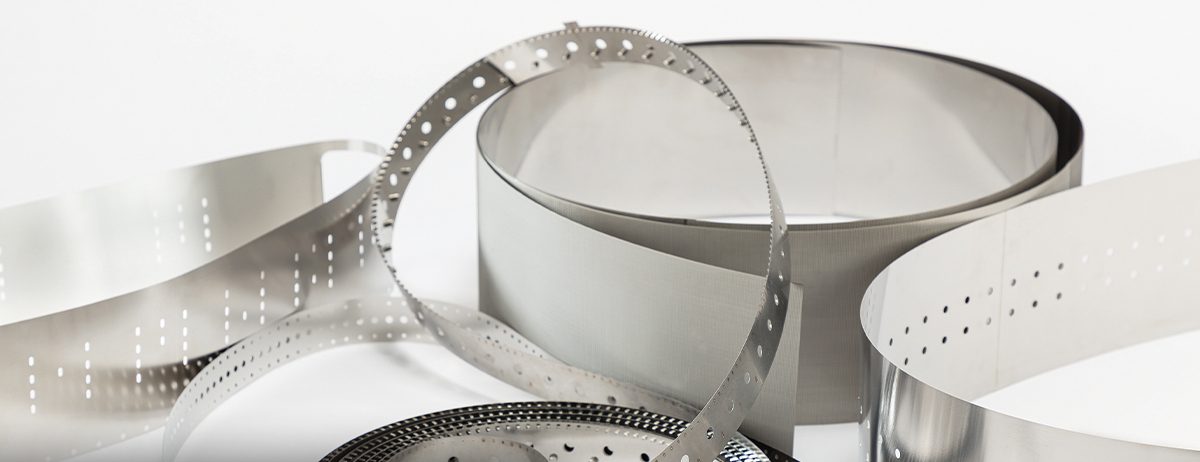

Material Selection: High-Strength Stainless Steel

Belt Technologies uses only high-strength stainless steel to manufacture our PureSteel products. This material offers unmatched resistance to temperature extremes, chemicals and contamination, making it ideal for applications in demanding automation environments like those found in food processing, electronics and pharmaceuticals. Stainless steel also ensures dimensional stability over time, reducing maintenance needs and minimizing downtime.

Precision Manufacturing and Welding Expertise

Our manufacturing process is built for accuracy. PureSteel® belts are fabricated to exacting standards, often with tolerances as tight as ±0.0005 inches. Welding is a critical part of our process, and it’s where our expertise truly stands out. Our skilled operators treat welding as both an art and a science, ensuring surface flatness, belt strength and joint integrity. Few manufacturers can match our consistency or level of craftsmanship.

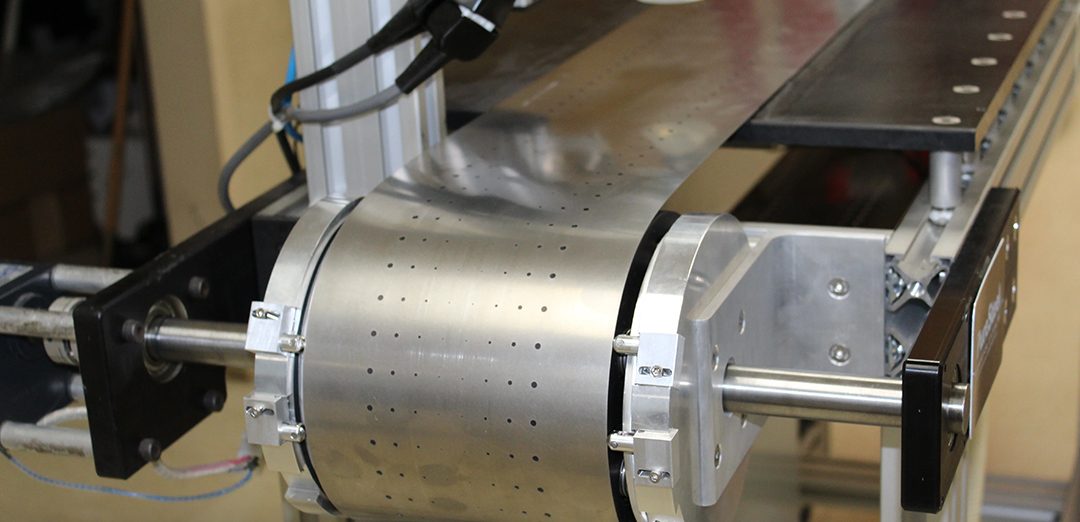

Component Integration: Beyond the Belt

A conveyor belt is only as effective as the system that drives it. Belt Technologies delivers complete, turnkey conveyor systems that include pulleys, metal framing, motor controls and vacuum systems when needed. Each component is designed to function as part of an integrated whole. This saves our customers time and ensures optimal system performance with minimal engineering overhead on their end.

Quality Assurance and ISO Certification

All PureSteel® products are manufactured under our ISO 9001-certified quality management system. We maintain strict quality controls at every stage of production to ensure compliance with industry standards and customer specifications. Each belt and system undergoes rigorous testing before it leaves our facility in Agawam, Massachusetts.

Tailored Solutions for Demanding Industries

From robotic surgery equipment to battery manufacturing lines, Belt Technologies serves a wide array of sectors where failure is not an option. Our solutions power applications that require high precision, repeatability and hygiene. For example, in cleanroom environments typical of the electronics industry, our belts perform with zero lubrication and generate minimal particulate.

Why Choose Belt Technologies?

Manufacturers worldwide rely on Belt Technologies because we do more than supply belts—we engineer results. Our PureSteel belts don’t stretch. They maintain accuracy across countless cycles. And they’re backed by decades of expertise and a collaborative process that puts your needs first.

Ready to optimize your automation system with a metal belt solution built for your environment? Contact our engineering team today to get started.

Robotic automation

Robotic automation

In the realm of industrial automation, precision and reliability are paramount. At Belt Technologies, we specialize in manufacturing stainless steel belts and conveyor systems that set the industry standard for accuracy, catering to design engineers dedicated to quality and continuous improvement.

In the realm of industrial automation, precision and reliability are paramount. At Belt Technologies, we specialize in manufacturing stainless steel belts and conveyor systems that set the industry standard for accuracy, catering to design engineers dedicated to quality and continuous improvement.