[et_pb_section fb_built=”1″ admin_label=”section” _builder_version=”4.16″ global_colors_info=”{}”][et_pb_row _builder_version=”4.16″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_text _builder_version=”4.23″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” use_border_color=”off” border_color=”#ffffff” border_style=”solid” global_colors_info=”{}”]

Industrial Automation for the Medical and Pharmaceutical Industries

[/et_pb_text][/et_pb_column][/et_pb_row][et_pb_row column_structure=”1_2,1_2″ _builder_version=”4.16″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” global_colors_info=”{}”][et_pb_column type=”1_2″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_text admin_label=”Why Consider Metal Belts for Your Application” _builder_version=”4.23″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” hover_enabled=”0″ use_border_color=”off” border_color=”#ffffff” border_style=”solid” global_colors_info=”{}” sticky_enabled=”0″]

It’s in Our DNA

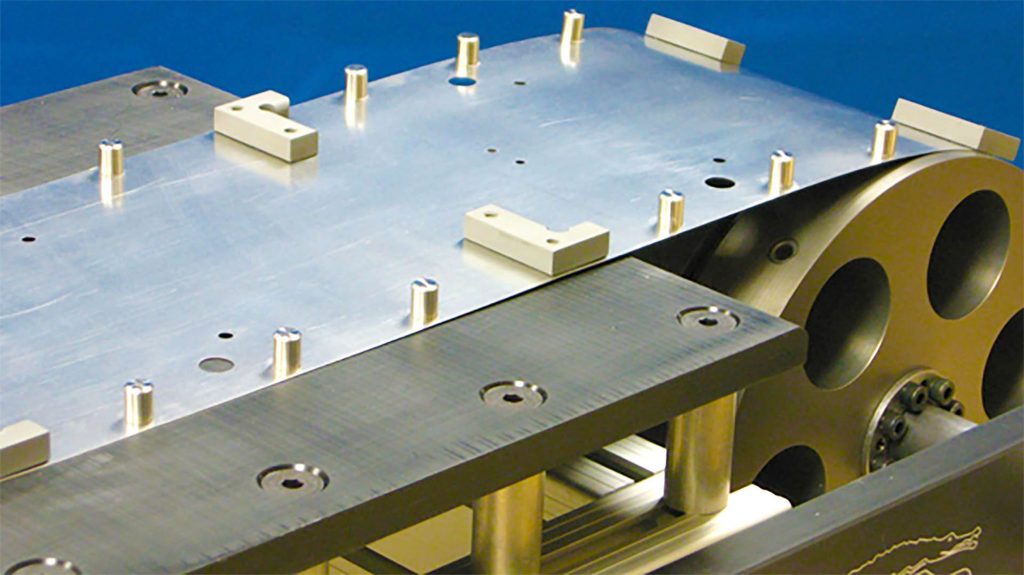

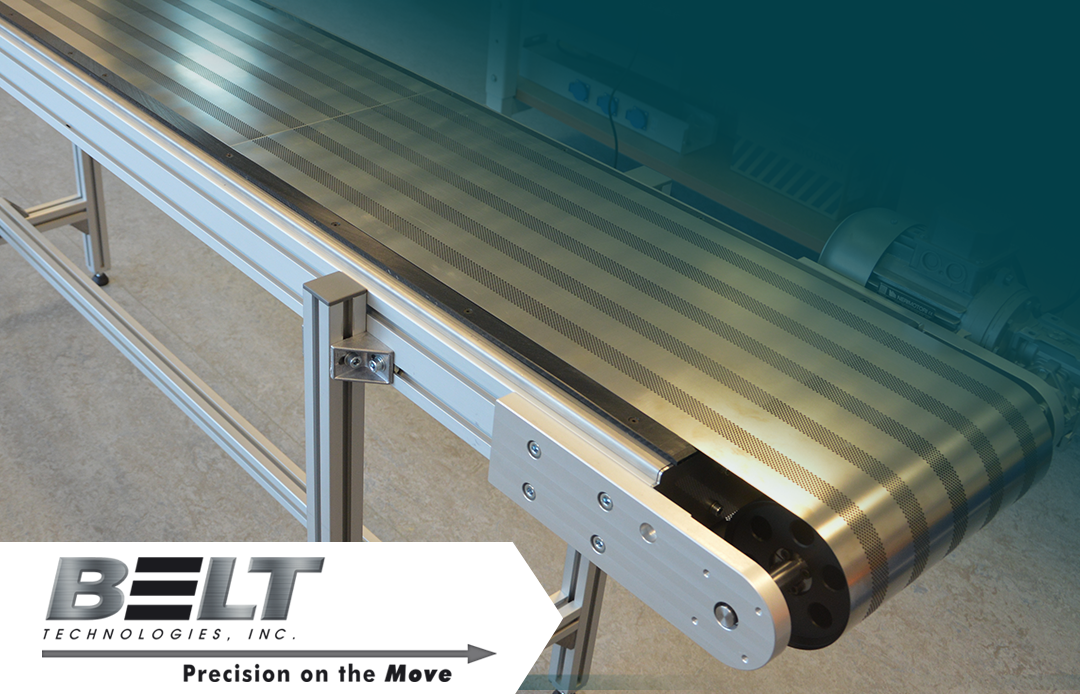

Our PureSteel® metal conveyor belts play a significant role in medical and pharmaceutical manufacturing, offering superior precision control, hygiene and customization options.

Our metal belts are:

- Sanitary

- Easy to clean

- Resistant to corrosion

- Strong

- Virtually non-stretchable

- Fully customizable

Download our free infographic to learn more about the benefits, applications and specs that make our PureSteel® metal conveyor belts the ideal solution for medical and pharmaceutical applications.

[/et_pb_text][/et_pb_column][et_pb_column type=”1_2″ _builder_version=”4.16″ custom_padding=”|||” global_colors_info=”{}” custom_padding__hover=”|||”][et_pb_text admin_label=”Download Form” module_class=”asset-download-text-module” _builder_version=”4.23″ z_index_tablet=”500″ text_text_shadow_horizontal_length_tablet=”0px” text_text_shadow_vertical_length_tablet=”0px” text_text_shadow_blur_strength_tablet=”1px” link_text_shadow_horizontal_length_tablet=”0px” link_text_shadow_vertical_length_tablet=”0px” link_text_shadow_blur_strength_tablet=”1px” ul_text_shadow_horizontal_length_tablet=”0px” ul_text_shadow_vertical_length_tablet=”0px” ul_text_shadow_blur_strength_tablet=”1px” ol_text_shadow_horizontal_length_tablet=”0px” ol_text_shadow_vertical_length_tablet=”0px” ol_text_shadow_blur_strength_tablet=”1px” quote_text_shadow_horizontal_length_tablet=”0px” quote_text_shadow_vertical_length_tablet=”0px” quote_text_shadow_blur_strength_tablet=”1px” header_text_shadow_horizontal_length_tablet=”0px” header_text_shadow_vertical_length_tablet=”0px” header_text_shadow_blur_strength_tablet=”1px” header_2_text_shadow_horizontal_length_tablet=”0px” header_2_text_shadow_vertical_length_tablet=”0px” header_2_text_shadow_blur_strength_tablet=”1px” header_3_text_shadow_horizontal_length_tablet=”0px” header_3_text_shadow_vertical_length_tablet=”0px” header_3_text_shadow_blur_strength_tablet=”1px” header_4_text_shadow_horizontal_length_tablet=”0px” header_4_text_shadow_vertical_length_tablet=”0px” header_4_text_shadow_blur_strength_tablet=”1px” header_5_text_shadow_horizontal_length_tablet=”0px” header_5_text_shadow_vertical_length_tablet=”0px” header_5_text_shadow_blur_strength_tablet=”1px” header_6_text_shadow_horizontal_length_tablet=”0px” header_6_text_shadow_vertical_length_tablet=”0px” header_6_text_shadow_blur_strength_tablet=”1px” box_shadow_horizontal_tablet=”0px” box_shadow_vertical_tablet=”0px” box_shadow_blur_tablet=”40px” box_shadow_spread_tablet=”0px” use_border_color=”on” border_color=”#dbdbdb” border_style=”solid” global_colors_info=”{}”]

Download Our Free Medical and Pharmaceutical Infographic

Please be sure to check your email junk folder if you do not receive the download.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

The new year is finally here, have you made a New Year’s resolution yet? We’re not talking about slimming down or getting to the gym, we’re talking about your business. It’s the perfect time to improve your productivity in 2021, and our line of

The new year is finally here, have you made a New Year’s resolution yet? We’re not talking about slimming down or getting to the gym, we’re talking about your business. It’s the perfect time to improve your productivity in 2021, and our line of