In today’s hypercompetitive environment, tobacco companies expect suppliers to enable them to develop attractive products while controlling costs and meeting government regulations. Read the article in Tobacco Reporter.

Author: Devon LaChance

Belt Technologies Recognized at Sixth Annual Manufacturing Awards Ceremony

Belt Technologies was honored at the sixth annual Manufacturing Awards Ceremony hosted by the Massachusetts Legislative Manufacturing Caucus at the Massachusetts Manufacturing Mash-Up event.

Read the full article.

How to Find the Right Belt for the Job

Are you looking for the right conveyor belt to meet the specific needs of your facility’s production? Look no further: in this blog, we’ll help you find the right belt for the job and explain why our PureSteel® metal belts provide all the necessary benefits to overcome your manufacturing challenges. Whether you use our drive tapes, timing belts or conveyor belts, our custom products and solutions will help to solve a wide range of automated manufacturing needs.

Are you looking for the right conveyor belt to meet the specific needs of your facility’s production? Look no further: in this blog, we’ll help you find the right belt for the job and explain why our PureSteel® metal belts provide all the necessary benefits to overcome your manufacturing challenges. Whether you use our drive tapes, timing belts or conveyor belts, our custom products and solutions will help to solve a wide range of automated manufacturing needs.

Meeting Your Needs

What matters most to you? Accuracy? Durability? Cleanroom compatibility? Choosing the solution that’s right for you isn’t always easy, so we’re outlining the specific strengths associated with some of our most popular products.

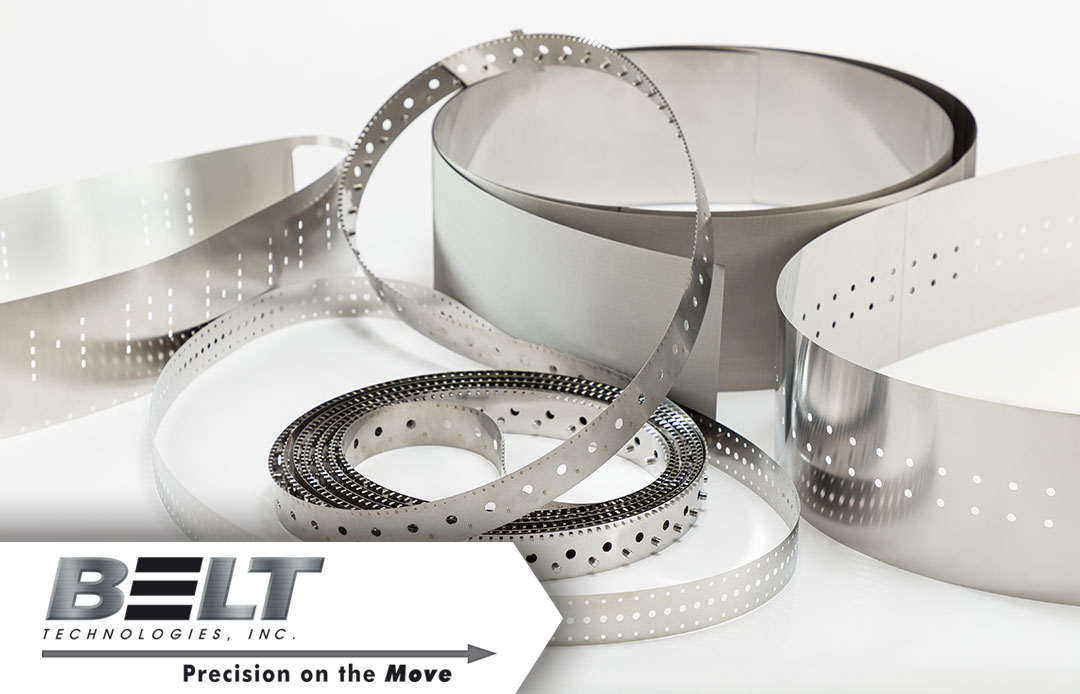

Endless belts: Our PureSteel® endless metal belts are created by welding together two ends of a metal strip, providing the same strength and versatility you can expect from all of our products. They meet strict sanitary requirements for food processing and pharmaceutical industries.

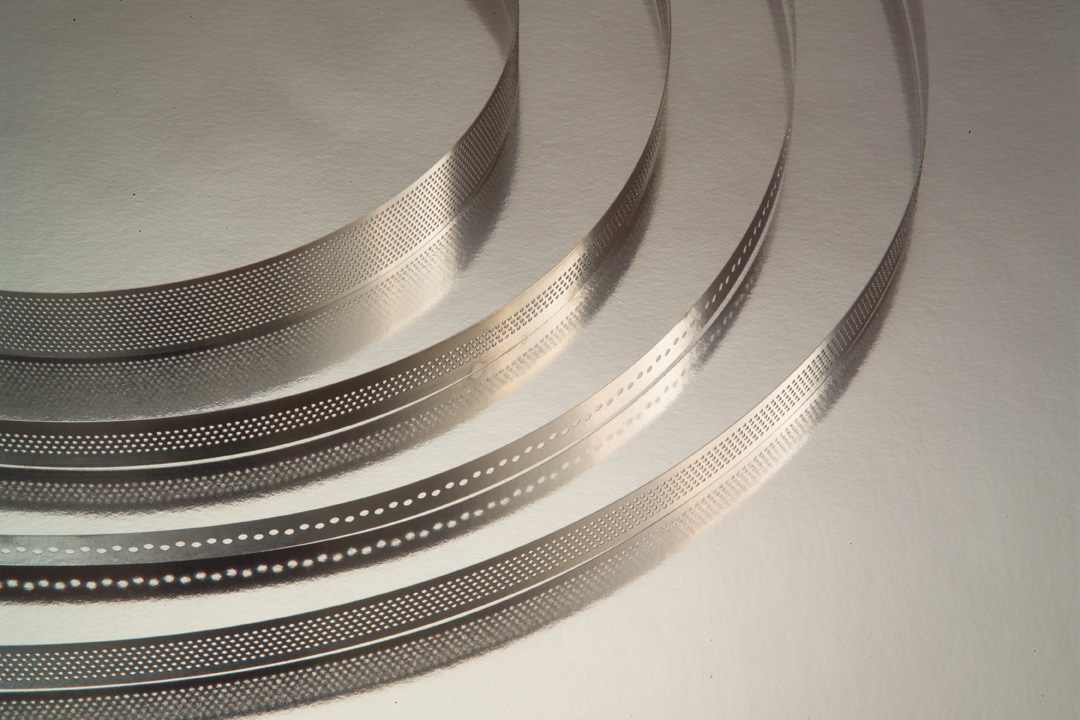

Perforated belts: Careful and exact placement of perforations, which drive the belt, ensures the precise and accurate positioning of products on its surface. Perforated belts are frequently used in vacuum conveying or for any industry in need of secure transportation, including solar panel production, medical device manufacturing, electronics manufacturing and more.

Timing belts and drive tapes: Designed to function with specialized timing pulleys to guarantee precise and cyclical transport of products. The perforations in these belts are created with a focus on timing elements and not motion generation, making them essential for carriage positioning, indexing and achieving accurate and repeatable results.

Multilayered drive tapes: Ideal for when strength and durability are necessary, but space is a concern. Multilayered drive tapes consist of multiple, stacked bands to increase belt strength while reducing pulley diameter, creating a perfect solution for heavy loads.

Friction drive belts: Belt motion is achieved from tension around two or more pulleys that drive the belt forward. Friction belts are the simplest, lowest cost solution in applications requiring relatively lower precision such as conveying, heat sealing, casting and imaging.

Other Materials Can’t Keep Up

No matter which of our solutions fits your specific production, our PureSteel® metal belts are way ahead of the competition. Unlike polyester, nylon or cotton belts with rubber or plastic covers, metal belts can withstand temperature extremes, vacuum conditions and caustic environments. They are not susceptible to stretching or warping and provide durability while maintaining lightweight flexibility for smooth, continuous operation. Additionally, metal belts do not require lubrication and do not generate particulates, making them cleanroom compatible and ideal for food and pharmaceutical processing.

Our engineers will work with you to find the right belt for the job and will create a custom solution tailored to your facility. Contact us to learn more.

Producers Struggle to Absorb Rising Prices

It has been a difficult time for all businesses through the pandemic, but manufacturers have prevailed through labor and material shortages, including Belt Technologies. CEO Denis Gagnon spoke with NTD News about the current trends in manufacturing.

View the interview here starting about eight minutes in.

The Unsung Heroes of Environmental Services Week

Over the past year and a half, we have all witnessed incredible work by those in the medical field to keep us safe during the COVID-19 pandemic, and more recently during the resurgence of the virus with the Delta Variant. During Environmental Services Week, from September 12–18, we would like to recognize the professionals on the front lines who don’t usually receive their due: environmental service (EVS) technicians.

Over the past year and a half, we have all witnessed incredible work by those in the medical field to keep us safe during the COVID-19 pandemic, and more recently during the resurgence of the virus with the Delta Variant. During Environmental Services Week, from September 12–18, we would like to recognize the professionals on the front lines who don’t usually receive their due: environmental service (EVS) technicians.

As a company that supports the medical industry with our PureSteel® stainless steel belts that operate in cleanroom environments, we want to take the time to acknowledge the critical efforts of EVS professionals while highlighting our supporting role.

What is an Environmental Service Professional?

EVS technicians are responsible for establishing and maintaining healthcare environments that are free of surface contamination and support safety, service and effective operations. They provide the necessary medical cleaning and disinfecting measures needed to keep every person in a given hospital or health care facility safe—and are the first defense against infection control. Without this work, doctors, surgeons, nurses and others wouldn’t be able to safely perform their critically important functions.

Stainless Steel Belts for the Medical and Pharmaceutical Industries

At Belt Technologies, we provide a similar service behind the scenes—creating PureSteel® stainless steel belts to carry medical and pharmaceutical equipment. Conveyor belts are an essential part of medical and pharmaceutical processing, so keeping them clean is a top priority. Our stainless steel belts have become a preferred choice, as they do not require lubrication and do not outgas, eliminating the risk of contamination. They also do not fray or generate particulates, like other belt materials, making them essential in cleanroom situations.

Our stainless steel conveyor systems are designed for easy access, providing savings in both facility maintenance and cleaning labor. Additionally, we can custom design and build them with your application in mind. If you are seeking a clean, customized conveyor system for your pharmaceutical or medical equipment processing needs, contact the experts at Belt Technologies today.

And remember, especially this week, if you know any EVS professionals, thank them for their work behind the scenes—none of the amazing progress during this pandemic would have been possible without them.

The Top Five Reasons Why Metal Belts Are Better than the Competition

With sophisticated technology and innovative manufacturing processes, we have produced metal conveyors, timing belts and pulleys for more than 50 years. Our superior PureSteel® products are used in a wide variety of industries and are trusted to consistently outperform the competition. With that in mind, here are the top five reasons why metal belts are better than traditional belt alternatives.

With sophisticated technology and innovative manufacturing processes, we have produced metal conveyors, timing belts and pulleys for more than 50 years. Our superior PureSteel® products are used in a wide variety of industries and are trusted to consistently outperform the competition. With that in mind, here are the top five reasons why metal belts are better than traditional belt alternatives.

1) Accuracy and Repeatability

Our steel belt technology offers unique designs which will guarantee zero slip and absolute precision, which is especially notable in our drive tapes and timing belts. Stainless steel drive tapes substantially reduce chordal vibration, motion loss and backlash that can often result in inaccurate positioning of robotic motion profiles.

When it comes to metal timing belts, our models can be fabricated with a pitch accuracy of ±0.0005 inches, which is understandably valuable in designing, indexing, positioning or processing equipment.

2) Cleanliness

Unlike other belting materials, metal belts don’t generate dust or particulates that could spoil or corrupt food or pharmaceutical products. Stainless steel’s nonporous surface resists contamination, a benefit for applications where food bacteria or other germs could gather in grooves, marks or scratches. Additionally, our PureSteel® belts do not require lubricants that would introduce foreign substances into a clean environment.

3) Durability

Whether it’s extreme temperatures or unforgiving environments, our metal belts can be engineered to handle virtually anything you can throw at them. Stainless steel has a low thermal coefficient of expansion, enabling it to better resist temperature extremes, and is also corrosion resistant and vacuum compatible. Inferior materials such as plastic, rubber or cloth will warp, burn or fall apart at significantly lower temperatures, and shrink or become brittle in extreme cold. Our Sales Engineers can help you select the correct alloy and belt thickness to suit the specific requirements of your operation.

4) Strength

Stainless steel has a tensile strength ranging from of 180 to 300 KPSI (thousand pound-force per square inch), depending on the alloy and temper of the metal. That means relatively thin and lightweight belts can be designed to handle the stresses of almost any application. The high strength and low weight let more of the conveyor’s input horsepower be devoted to moving the product and not the belt, which boosts efficiency and reduces operating expenses. Simply put, metal belts are stronger and more efficient than the alternatives.

5) Customization

If you have a problem, we have a customized solution fabricated to meet your exact specifications. We’ve perfected the engineering of our PureSteel® belts, so you can trust us to design a unique belt to meet your exact needs. This includes a broad array of metal alloys, belt width and thickness combinations, perforation, patterns, coatings and attachments.

Do you think your operation could benefit from a stainless steel conveyor system? Contact us today, so we can start planning and providing the custom solutions you need.

Building Better Electric Vehicle Batteries with Metal Belts

The world is going green with various methods to lower harmful emissions, and industries across the board are making the necessary changes to keep up. Belt Technologies Inc., a manufacturer of custom metal belt conveyer solutions and conveyor systems for more than five decades, is providing a crucial service for vehicle battery manufacturers as their demands shift from lead acid to electric. Read More

The world is going green with various methods to lower harmful emissions, and industries across the board are making the necessary changes to keep up. Belt Technologies Inc., a manufacturer of custom metal belt conveyer solutions and conveyor systems for more than five decades, is providing a crucial service for vehicle battery manufacturers as their demands shift from lead acid to electric. Read More

How Can We Help You? It’s Get to Know Your Customers Day

Hello, we’re Belt Technologies; how can we help you? July 15 is Get to Know Your Customers Day, a quarterly observance held in January, April, July and October—but we like to know our customers every day of the year, understanding and exceeding your expectations on each individual project. In this blog, we’re highlighting how we’ve done just that for a few of our previous customers.

Hello, we’re Belt Technologies; how can we help you? July 15 is Get to Know Your Customers Day, a quarterly observance held in January, April, July and October—but we like to know our customers every day of the year, understanding and exceeding your expectations on each individual project. In this blog, we’re highlighting how we’ve done just that for a few of our previous customers.

Understanding Needs

Our team will always go above and beyond to understand and ensure your needs are met, providing solutions for the problems you face. For example, a U.S. medical manufacturer creating DNA test kits required exponentially improved productivity with reduced operating costs. Our engineers put their heads together and created a belt that could run four separate products on the same line, increasing profits and helping propel the medical industry forward. After that success, the company turned to us to assist in the production of COVID-19 testing kits during the height of the pandemic.

Building Relationships One Belt at a Time

We also understand the importance of building relationships, which drives our dedication to provide exemplary, personalized service to our individual customers. We were recently contacted by a group of students at California State University Long Beach for help with a project in their Senior Design class. The students were creating a hand-crank tamale maker and were in need of a sanitary conveyor solution. Recognizing their entrepreneurial spirit, we helped them with the design of a perforated endless belt.

Customizing Solutions

If you have a problem, we have a customized solution. Recently, we worked with a client attempting to move their projects toward commercialization in the robotics field. They required a system that could lift and rotate very heavy loads, which they needed to achieve in a way that would not change the diameter size of their pulley. They turned to us for a custom solution, and we gave them one: a multilayered belt that allowed for much higher torque than a traditional belt with a pulley of the same size.

Discover How We Can Help You

So, as a potential customer, we want to know: how can we help you? Contact us today, so we can get to know you, your operation and your goals—and start planning and providing the solutions you need.

Top 5 Benefits of Vertical Conveyors

Our vertical conveyor systems are not to be confused with elevator, spiral or reciprocating systems. No—our unique take on a vertical conveyor turns a horizontal conveyor on its side, positioning the conveyor belt surface vertically. This unique belt-positioning brings with it a number of advantages. In this blog, we’ll explore the top 5 benefits of vertical conveyors and share some design considerations.

Benefit 1: Increased Productivity

By using both sides of the conveyor belt, the output is doubled. This is especially helpful when:

By using both sides of the conveyor belt, the output is doubled. This is especially helpful when:

- Producing or processing medical devices

- Plating and/or coating products

- Creatively transporting uniquely shaped products

Despite the extra output, our vertical conveyors do not require any extra floor space. Compact and efficient, they truly are a win-win for a company looking for a unique solution to increase profits, offset an investment of another type of equipment—or both.

Benefit 2: Cost-Effectiveness

Despite doubling output, operational costs to run a vertical conveyor are the same as traditional, horizontal conveyors. In fact, in some applications, costs are decreased with the vertical option, especially if multiple products are being transported at a time. (See Benefit 3.)

Benefit 3: Flexibility

A key benefit of vertical conveyor systems is their flexibility—but it’s two-fold.

- Vertical conveyors are able to transport more than one type of product at a time. This helps to reduce manpower needed on an assembly line to work on changeovers or reconfigurations on a shop floor.

- In addition, metal belts and conveyor systems have a high resistance to both chemical corrosion and extreme temperatures, making them appropriate for use across a wide variety of industries.

Benefit 4: Cleanliness

The medical and food industries are but two that benefit from vertical conveyors.

- Metal vertical conveyor systems are easy to clean and resistant to bacterial adhesion. This keeps medical tools and products hygienic and food products safe to consume.

- Likewise, with minimal touchpoints, medical or food products are less likely to accumulate debris, helping customers from both industries meet stringent safety standards.

- And because they do not require any lubricants, the medical or food items being transported are not susceptible to contamination.

You can hear more about the benefits a vertical conveyor offered one of our medical customers in this case study. Notably, the system has been running flawlessly since 1999 and contributed to the production of COVID-19 test kits during the height of the pandemic.

Benefit 5: Customization Options

No matter your industry or application, our experts can customize a vertical conveyor to suit your budget and meet your objectives. Choose from:

- Surface coatings and treatments to optimize product handling

- Custom perforations to aid in product tracking and transport

- Attachment integration

- And more

Building a vertical conveyor requires an innovative approach to engineering a solution. Our design experts give special attention to the relationship between the belt and its pulleys to guarantee the belt will not slip during normal operation. We’ve successfully developed methods to ensure belt alignment for numerous vertical systems and are prepared to assist with this important design element for your application. Ready to start designing? Contact us today.

Helping Our Heroes during National Hospital Week 2021

This past year has been difficult for everyone, but that’s especially true for medical workers who selflessly put their health on the line during the height of the COVID-19 pandemic to ensure the health and safety of others. National Hospital Week 2021 runs from May 9 through May 15; it’s a time to thank all of the health care employees who have worked tirelessly to help us all. It also provides a platform for us to highlight the ways our metal belts continue to help support the industry behind the scenes.

Just What the Doctor Ordered

Medical equipment is held to a higher safety standard than other products—the materials used to process, handle and transport it need to be bacteria resistant and easy to clean. Additionally, surgical robotics rely on extreme precision and accuracy to perform their delicate functions. Medical manufacturers often turn to Belt Technologies because our stainless steel belts embody all of these qualities.

Medical equipment is held to a higher safety standard than other products—the materials used to process, handle and transport it need to be bacteria resistant and easy to clean. Additionally, surgical robotics rely on extreme precision and accuracy to perform their delicate functions. Medical manufacturers often turn to Belt Technologies because our stainless steel belts embody all of these qualities.

Our belts have:

- A smooth and impermeable surface to prevent the housing of microbes or bacteria, which can thrive in other belt materials like rubber or plastic.

- High resistance to corrosion, which allows the belts to be sanitized with high-pressure steam, high-pressure wash and chemical cleaning.

- High heat resistance, allowing them to be thoroughly sterilized.

- The ability to be designed for zero-backlash with high life cycle requirements in surgical robotics applications.

It is due to these aspects, and due to our reputation for expert support from concept to completion, that medical personnel turn to Belt in the manufacturing process for medical equipment. Our belts provide a minimal risk of contamination and maximum compliance with existing regulations.

Success Is in Our DNA

Prior to the COVID-19 pandemic, a molecular diagnostics company reached out to us to improve their production for revolutionary DNA analysis technology. The company was producing 400 disposable reaction tubes per day for DNA test kits and the need arose to produce more. The company opted for a metal belt conveyor system with both the pulleys and belts supplied from Belt Technologies. We improved their process times while simultaneously altering their configuration to allow for four separate products to be run on the same line—which led to increased output—18 million units per year—not to mention increased profits and impressive strides in the medical field.

One success led to another and the company chose us to assist in the production of COVID-19 test kits at the height of the pandemic. We were happy to do our part to supply medical professionals with the tools they need to do their jobs, and we would be happy to do the same for you. Contact us if you think we can help your company with a personalized solution. And remember to take some time this week to thank any of the health care professionals in your life.