What new products are we introducing? How was our company impacted by the pandemic? Find out answers to these questions and more in this Easy Engineering International piece.

What new products are we introducing? How was our company impacted by the pandemic? Find out answers to these questions and more in this Easy Engineering International piece.

There are few things that can really spark a child’s imagination the way that robots can—from R2D2 to the Mars 2020 Perseverance Rover. That’s where National Robotics Week comes in. Running from April 3 through April 11, the mission of the observance week is to inspire students to explore science, technology, engineering and mathematics (STEM) related fields, including careers in robotics. We proudly support this goal and will continue to celebrate National Robotics Week as we manufacture belts that propel the industry forward.

The success of the robotics field is based on the ability to provide actions that are both highly accurate and consistently repeatable. That description perfectly sums up all of our non-stretchable, stainless steel products, but especially our drive tapes and timing belts which are able to perform with near-zero backlash, both of which have been implemented in the following:

At Belt Technologies, we can work with you to develop a unique solution for your robotics application. We were previously approached by a company producing automated robotic equipment for the dairy industry. The customer’s equipment included a robotic arm that controlled milking attachments designed to attach to a cow’s udder.

A metal band on the arm was experiencing a high rate of failure due to poor attachment points and a high level of torque. Our engineers worked with the customer to remove the high bending loads and extend the lifespan of the belt.

Belt Technologies’ drive tapes also empower a large number of robotic applications in the medical, semiconductor and industrial fields. Our stainless steel drive tapes and timing belts can also meet the demanding needs of your application, and, if necessary, many of our engineers have the knowledge and experience to help with your customized design. Contact us today to find out how we can help with your robotics or automation system. And remember, during National Robotics Week, we’re recognizing the amazing work that continues to be done in this quickly growing industry, and we’re proud of the part we’ve been able to play to help it move forward. We hope our solutions help to inspire future engineers into STEM careers, including robotics.

Today is National Frozen Food Day, a time to recognize how advances in food preservation have improved our modern lives. From ice cream to pizza to meat, we understand the importance of food preservation and think it’s a perfect time to tout our ongoing work in food processing solutions.

Stainless steel metal conveyor belts are excellent for cooking, freezing and handling edible products, offering a variety of benefits over belts made out of traditional materials. Metal belts do not require lubrication, meaning that there is no risk of chemicals tainting the food. Additionally, stainless steel is resistant to bacteria, making belts produced from this material easy to clean and in conformance of even the strictest USDA requirements. Due to the nature of stainless steel, there is also no concern of fraying, which can happen with other materials, leading to particulates contaminating food products.

The most important aspect to highlight on National Frozen Food Day is the resistance metal belts have to extreme temperatures. Stainless steel can withstand cooking and freezing processes that food products are frequently subjected to during manufacturing—meaning that facilities using metal belts on their production line can more easily automate their processes and handle the food less throughout them—just adding to hygiene and overall efficiency.

As an example, we helped a customer design a belt that could operate in temperatures as low as -40°F. The customer’s setup needed to compress a meat product at high speeds between a freezing drum and the belt. We developed a combined solution that included a solid metal belt and a piano hinge termination to make it easier to clean and load the machine.

As an example, we helped a customer design a belt that could operate in temperatures as low as -40°F. The customer’s setup needed to compress a meat product at high speeds between a freezing drum and the belt. We developed a combined solution that included a solid metal belt and a piano hinge termination to make it easier to clean and load the machine.

In another instance, a company specializing in gourmet butter products was in need of a belt that would operate in temperatures under -150°F. They were originally working with a standard Teflon-coated fabric belt but due to the nature of their product, constant cleaning was a necessity. The traditional belts needed to be replaced every 3–4 weeks due to constant abrasion from the cleaning process. When the facility switched to our stainless steel belts, the time between operational shutdown was increased to 6–12 weeks. The company was so satisfied they also bought a metal belt for a second machine.

Stainless steel belts are the most sanitary and reliable option on the market, perfect for any food application. In honor of National Frozen Food Day, enjoy your favorite frozen meal and contact us to learn how we can help you create a customized food processing solution.

For more than 10,000 years, producing tamales has been tedious and time-consuming, until now, thanks to an inventive team of senior design engineers at California State University Long Beach and custom metal belt manufacturer, Belt Technologies, Inc.

For more than 10,000 years, producing tamales has been tedious and time-consuming, until now, thanks to an inventive team of senior design engineers at California State University Long Beach and custom metal belt manufacturer, Belt Technologies, Inc.

From roads to computers to metal conveyor belts—engineers create and design the products that make our world run. Now, it’s time to recognize them as part of National Engineers Week. At Belt Technologies, we’re celebrating the engineers involved in our work with three fun facts about engineering.

A little history before we get to the facts: engineering week (EWeek) was founded by the National Society of Professional Engineers 70 years ago. Its goal has been dedicated to ensuring a diverse and well-educated future engineering workforce by stressing the importance of STEM (science, technology, engineering and math) literacy. This is something we absolutely support and practice through the educational opportunities we offer our employees, and the interns and students we’ve mentored.

Most recently, we worked with a group of students at California State University to complete a final project in a senior design class. We were pleased to learn of how the team was able to integrate a PureSteel TM perforated endless belt into the design of a hand crank tamale maker and applaud their entrepreneurial spirit and (tasty) results.

This year, we hope you’ll join us in celebrating future engineers during National Engineers Week from Sunday, February 21 to Saturday, February 27.

Engineering Fun Facts

Engineering Fun FactsDo you know who the first engineer in the United States was? Believe it or not, it was our first President, George Washington! It’s no coincidence that National Engineers Week is celebrated in conjunction with his birthday—February 22.

Before he led the United States and even before he was a general in the Revolutionary War, Washington was a land surveyor in Virginia. In his work, he mapped out boundaries, established property lines and developed plans for straight roads through rough terrain.

Much like George Washington, we could be considered a pioneer by some with the introduction of our “revolutionary” products.

It’s not probably something you think about while at an amusement park, but the Ferris Wheel is actually considered one of the greatest engineering wonders in the world—and the story behind it is equally fascinating. In 1893, the city of Chicago won the right to hold the World’s Fair. At the previous exposition in 1889, the city of Paris unveiled the Eiffel Tower, so the expectations were high. Engineer George W. Ferris unveiled the original massive wheel which was supported by two 140-foot steel towers and connected by a 45-foot axle. It was the largest single piece of forged steel ever created at the time. The wheel was comprised of 36 separate gondolas which were capable of holding up to 60 people each, for a grand total capacity of 2,160 passengers!

The sheer size and capacity stretched the limits of what was considered possible. We are doing the same with our metal belts, pushing the limits of durability and tolerance. Of special note are our multi-layered belts. Offering even greater strength and durability than our single-layer variants, our multi-layered belts are manufactured by precisely cutting equal lengths of metal and welding each together for a smooth and strong finish. An engineering marvel like the Ferris wheel? We’d say so.

One of the most famous civil engineering marvels in the world was created with techniques that were untested and unproven to work. A massive concrete structure like the dam had never been attempted before. The Hoover Dam contains so much concrete that it had to be poured block by block utilizing a complicated cooling system.

Completed in 1935, the dam still generates 4 billion kilowatt-hours of hydroelectric power each year. Much like the Hoover Dam, we are breaking new ground with the custom and off-the-shelf solutions we provide for use in robotics and industrial automation applications.

National Engineers Week is a great time to celebrate all of this history, but it’s also a time for us to honor the engineers who make our work at Belt Technologies possible. Our engineers will work with you to design and customize a metal belt that fits your facility’s needs. Contact us for more information on how engineers can increase your efficiency and save you money.

Also, remember to recognize the engineers in your life and make sure you wish them a happy National Engineers Week!

Machine Design compares and contrasts single and multi-layered metal belts in this editorial. Read on to find out which will benefit your next design or application. View Article

Machine Design compares and contrasts single and multi-layered metal belts in this editorial. Read on to find out which will benefit your next design or application. View Article

It is believed that tamales originated as early as 8000 to 5000 BC in Mesoamerica. Adopted by Aztec and Mayan civilizations and then Mexican and Guatemalan cultures, tamales are enjoyed for their portability and versatility. Made of masa or dough steamed in a corn husk or banana leaf, tamales can be stuffed with meats, cheeses, fruits, vegetables, chilies, or any combination thereof. While eating them is easy, producing them can be tedious. It is for this reason that tamales are typically mass produced, often around the holidays, to be stored and enjoyed throughout the following year.

When engineering student Alejandra Marroquin had the opportunity to improve the time-consuming process, she seized the opportunity, putting her manufacturing knowledge and mechanical inclinations to use in her Senior Design class at California State University Long Beach.

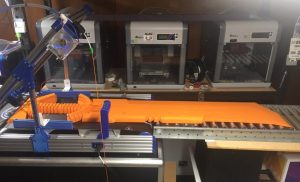

Alejandra’s Senior Design professor placed students into groups, and allowed each to plan, design and produce a working prototype as their final project. Alejandra and her partners quickly settled on the prototype to produce: a hand-crank tamale maker. The idea was to cut down on the amount of time necessary to produce each tamale, and moreover, cut down on the manual stretching and rolling required.

Students used computer-aided design software, SolidWorks, to plan and map out the design of their assembly. Taking into consideration the various stages of tamale production—the extrusion of dough or masa, dispersion of filling, folding of the corn husk—they also considered how best to achieve a proper gear ratio and timing system. From the beginning, the students recognized the need for food grade parts including gears, a crank and conveyor belt, all of which they intended to source or fabricate.

In researching sanitary conveyor belts through an online search, Alejandra learned of and contacted Belt Technologies to discuss her project and to place what she believed would be an order. Recognizing the students’ entrepreneurial spirit and design sense, Belt was happy to deliver a gratis perforated endless belt. Not only did the belt meet the design specs, but it was also a durable and sanitary addition to the newly devised kitchen equipment, meeting safe food handling recommendations of the Food and Drug Administration.

The prototype developed is a mechanical tamale maker driven by a hand crank. After latching a corn husk into a slot on the stainless steel belt from Belt Technologies, the user must rotate the crank clockwise to engage gears that will move the tamale through each stage of production. This is accomplished smoothly, hygienically and with significantly less effort than one would exert if producing a tamale by hand.

Of the results, Alejandra Marroquin expressed appreciation for Belt Technologies, stating that, “The conveyor is really at the heart of the prototype. We are so grateful to Michael Loomer [Belt Technologies’ Business Development Manager] who not only helped with the part design but also with the fabrication and shipping.”

Michael Loomer was equally appreciative of the opportunity to contribute to the project sharing, “We always are up to a design challenge and although this was a student project, our design intake, consultation and design was not dissimilar from a traditional company order. We’re happy to hear that our product aided in the finished project and wish Alejandra and her team members continued success in the future.”

Every year on December 3 (3D) we celebrate 3D Printing Day. We hope we can convince you to join us in celebrating 3D Printing Day, too, by sharing some interesting things that have been 3D printed as well as some ways we have been fortunate to advance the industry.

To construct complex parts quickly and cost effectively, many manufacturers elect to use 3D printers, machines capable of producing three dimensional parts by way of additive manufacturing. This entails using a digital file to guide a machine to lay down successive layers of material, often plastic, to form a solid end product.

While the concept of 3D printing is still relatively new, a recent viral story helped it gain some mainstream understanding and acceptance. Earlier this year, Robert Downey, Jr. as Iron Man, delivered a 3D printed prosthetic arm to a grateful recipient. You can learn about his story here.

This touching story represents just one example of the infinite possibilities for 3D printing, including those produced by our customers. For instance, we helped one customer, a leading manufacturer of large scale industrial 3D printing equipment, to produce prototype designs for boat hulls, helicopter rotors and even a submarine nose cone. We also have the pleasure of working with a number of small independent 3D printers producing a myriad array of parts and even an 8-foot-long plastic sword. In each case, the mobility and precision provided by an endless stainless steel belt that can also stand up to the high heat generated by the printing process was critical to the performance of these machines.

We are regularly contacted by 3D printer OEMs to develop and fabricate parts of all shapes and sizes that aid in the 3D printing process. Why?

Above all else, our products improve efficiencies and runtimes of 3D printing projects, helping to reduce labor expenses while increasing profit margins for companies large and small. Interested in learning more? Contact the experts at Belt Technologies for more information about our 3D printer drive tape, timing tape and pulley manufacturing capabilities.

Did you know that, for every $1.00 spent in manufacturing, another $2.74 is added to the economy?1 Or that for every one worker in manufacturing, five more are hired elsewhere? 1 If you ask us, these are compelling enough reasons to do business with American companies, but we’re here to offer even more. If you’ve been here before, you may already know that we hail from the Bay State, and all of our products are produced in America. Throughout this blog, we’ll discuss why American made matters and share a bit more about our company.

Did you know that, for every $1.00 spent in manufacturing, another $2.74 is added to the economy?1 Or that for every one worker in manufacturing, five more are hired elsewhere? 1 If you ask us, these are compelling enough reasons to do business with American companies, but we’re here to offer even more. If you’ve been here before, you may already know that we hail from the Bay State, and all of our products are produced in America. Throughout this blog, we’ll discuss why American made matters and share a bit more about our company.

Manufacturing facilities in the United States are highly regulated to ensure worker safety, compliance with labor laws and the issuance of fair wages. We are happy to report that the majority of our workforce has grown with us, with 25% working for us for 20 years or more. We are also a diverse team, with women and minorities representing 44% of our U.S. workforce. We’d like to believe that it’s our company culture and offerings that contribute to this longevity. If you’re interested in joining our team, available positions are posted here.

American manufacturers take pride in producing high-quality, durable products made from the finest raw materials and produced by skilled craftsmen overseen by experienced engineers and manufacturing managers. We are no exception. All of our metal belts undergo stringent quality inspections, and our results are precise: we are able to fabricate metal belts with a station-to-station pitch accuracy of ±0.0005”.

We are conscious of our company’s environmental impact, and for that reason, we source materials locally whenever possible, and employ a company recycling program. And, unlike alternative belts like neoprene or fabric, metal is naturally occurring and able to be recycled, making our products a more sustainable option.

Belt Technologies is proud to be an American manufacturer of metal belts, timing belts, metal drive tapes and custom metal belt conveyor systems. When you do business with our company, we hope you’ll take pride in your decision to partner with us.

1 – National Association of Manufacturers (NAM) calculations using 2018 IMPLAN data

Celebrating National Manufacturing Day

Celebrating National Manufacturing DayThe first Friday of October is National Manufacturing Day, which coincidentally is also recognized as National Apple Betty Day. In fact, the month of October is riddled with national food observance days. Having a hand in manufacturing precision and, specifically, contributing to the food industry, we thought we’d meet in the middle with this blog touching upon both areas of our expertise.

Members of our manufacturing team possess backgrounds in industrial engineering, mechanical engineering and welding technology. Together, they manufacture our products using sophisticated technology and innovative processes. Drawing from experience, and considering client needs and desired results, they work alongside our customers to create metal belts, belt components and complete conveyor systems that are fabricated to meet exact specifications.

With skill and pride to ensure exact measurements that will maximize product throughput and quality, we live up to our tagline: “precision on the move.”

It may surprise you to learn that our metal belts can easily transition from a cooking stage to a freezing stage in a food-handling process. This makes them ideal for use in almost every food-handling industry application, including fast food, dairy, frozen foods, seafood and others. This video details how our products are used in these types of applications.

In fact, the properties of our belts make them appropriate in the following ways, and for the following food observation days:

Are you a member of the food industry who could benefit from our stainless steel solutions? Or are you interested in learning how our manufacturing precision could benefit your organization or application? Give us a call.