An effective solution to reduce food recalls and increase consumer safety

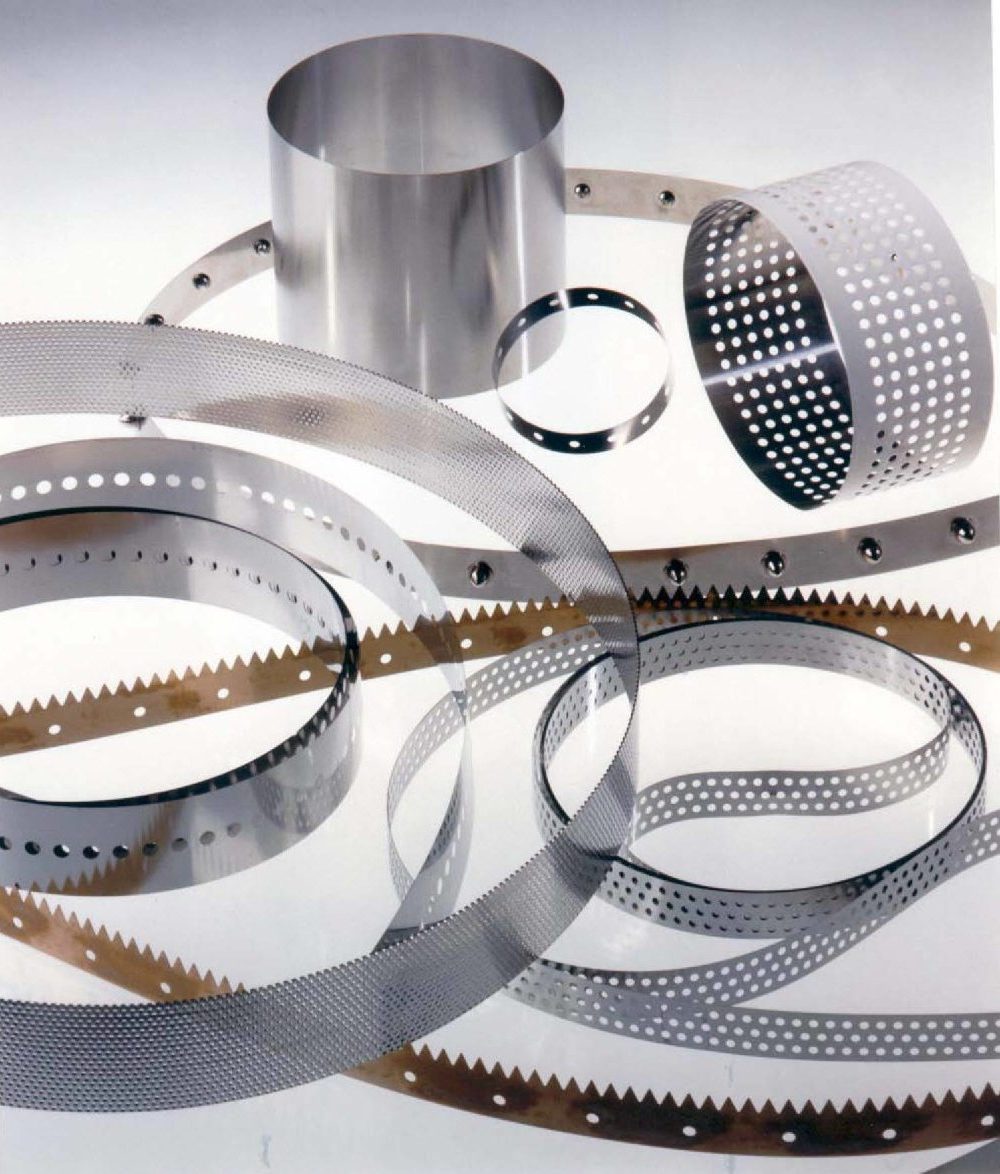

The food processing industry is ripe with product recalls, most often due to bacterial contaminants that spread through poorly inspected product or because of product contamination by dirty processing equipment. With widespread coronavirus concerns, especially in meat processing plants, there is a stronger demand than ever for safer, more hygienic practices throughout the food industry. Belt Technologies, Inc., manufacturer of custom metal belt conveyor solutions and conveyor systems for more than five decades, provides a hygienic solution: solid stainless steel belts and conveyor systems.

“Product recalls can be devastating for manufacturers and consumers,” said Mike Loomer, business development manager for the Americas. “And inferior equipment materials, such as plastic or rubber conveyor belts, can represent a needless risk to product quality. Incorporating stainless steel components into food processing equipment reduces such risk.”

Loomer explained that due to aging and repeated use, plastic and rubber belts can fray and generate particulates that can directly contaminate food, and are also susceptible to physical damage including pits, divots and cracks where chemicals, allergens or contagions can fester. They can also outgas (emit fumes), affecting food flavor. In comparison, solid stainless steel conveyor systems provide hygienic surfaces that are more sanitary and do not affect food quality.

“Metal conveyor belts do not require lubrication and do not outgas, so there is no risk to product flavor,” said Loomer. “Their solid, non-porous surface is resistant to bacteria, providing an overall cleaner surface area for transporting edible materials. They are also much easier to clean and sanitize.”

Because endless metal belts are resistant to high temperatures and corrosion, the conveyor systems can easily be cleaned with chlorine, high-pressure steam or most other washing methods. Stainless steel can also handle extreme temperatures, making it ideal to use in cooking or freezing processes.

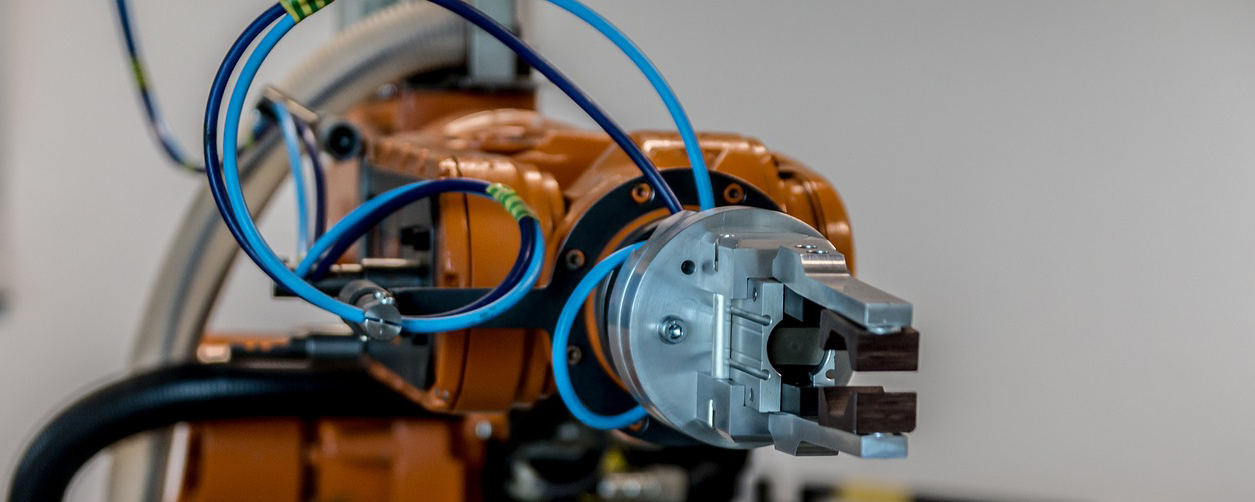

“The use of stainless steel belts in an automated food processing system helps guarantee sanitary, efficient and reliable product quality results,” said Loomer. “Our engineers can design metal belts to fit into and upgrade an existing automated food processing system, or help fabricate a custom solution. Endless metal belts consistently deliver exceptional results in the safe cooking, freezing and handling of edible products any time, but especially in response to today’s heightened hygiene concerns.”

May is

May is

April 4–12 is

April 4–12 is