Belt Technologies is building up its global presence by connecting with customers in emerging, worldwide technological markets. A major initiative of this strategy is to meet with global partners and industry leaders at international trade shows; this helps raise awareness of our unique metal belt solutions. These trade shows allow us to share how metal belts can catalyze growth in industries like robotics, industrial automation, capital equipment production, and medical instrumentation manufacturing.

Connecting Metal Belt and Drive Tape Solutions with International Customers

To support our diverse client base, we employ a multilingual workforce capable of handling inquiries from around the world. Several of our sales engineers, customer service reps, and global distributors are able to fluently communicate with international customers in a broad range of languages, including:

- English

- Spanish

- French

- Portuguese

- Italian

- German

- Dutch

- Japanese

- Chinese

- Russian

Exhibiting at high–tech shows via our global partners gives Belt Technologies considerable reach and local market support.

Recent Automation and Robotics Trade Shows in Brazil and Taiwan

One of our most recent exhibits included “FISPAL Tecnologia,” an international trade show for the Latin American automated food and beverage industries. This year’s event was held from June 14-17 at Anhembi Show Pavilion in São Paulo. The event takes place each year in Brazil, which is a strong emerging market for industrial machinery. The inherent qualities of our stainless steel conveyor belts make them an ideal fit for the food processing industry. They do not require lubrication, are highly sanitary, and are resistant to extreme temperatures such as those necessary for the cooking or freezing of food products.

Belt Technologies also recently attended the 2016 Taiwan Automation Intelligence and Robot Show (TAIROS), which took place at the TWTC Nangang Exhibition Hall from August 31 to September 3. With its booming robotics and automation industries, Asia is a crucial market for metal belts and drive tapes. Our metal drive tapes, for example, are excellent for robotics applications. They have near-zero backlash, are virtually non-stretchable, and provide exceptionally precise positional accuracy.

Building a Global Automation and Robotics Technology Network

Our presence at trade shows is part of a deliberate effort to connect with customers around the world. We always strive to provide hands-on demonstrations, build new networks of customers and vendors, refresh existing customer contacts, and make our sales engineers available to discuss the individual needs of our customers’ applications.

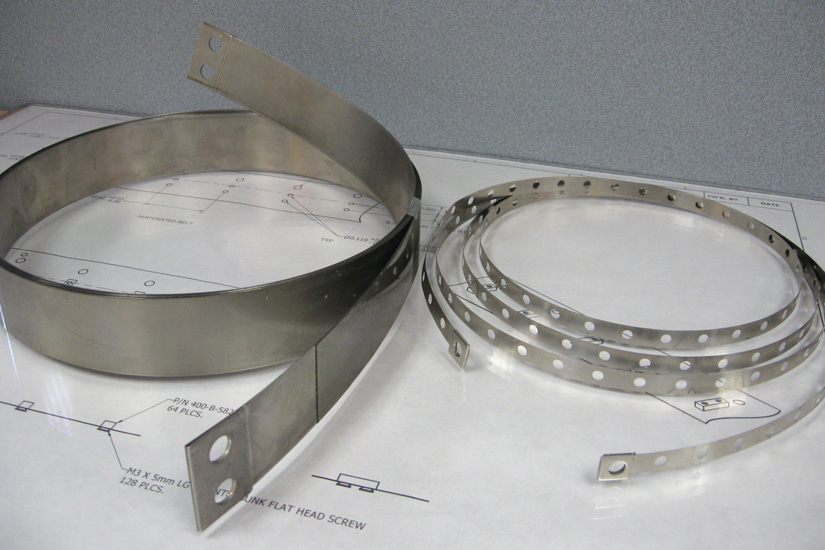

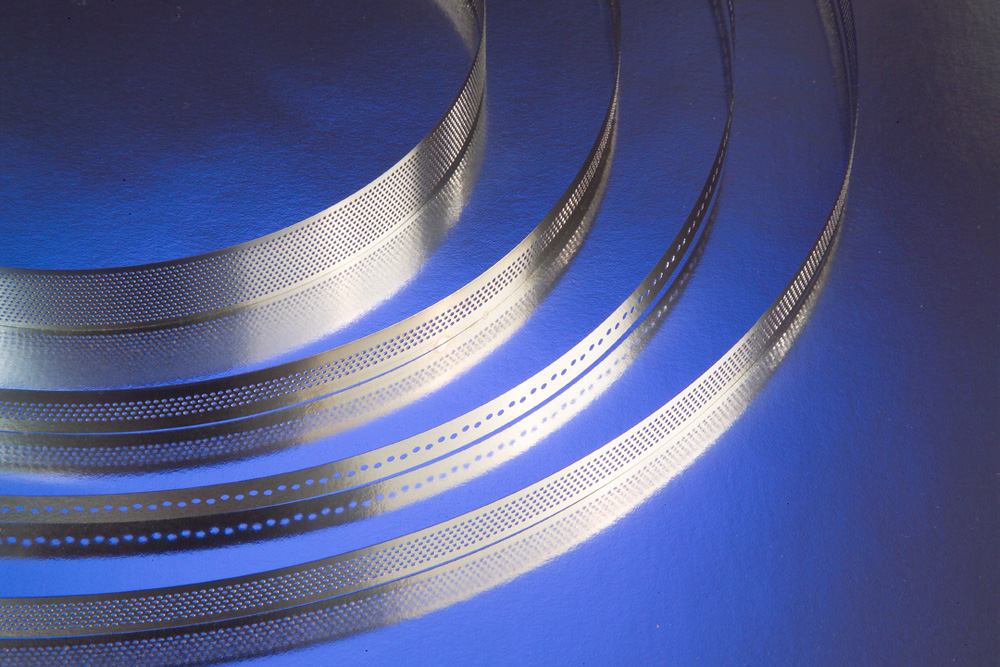

Our custom, stainless steel belt conveyor systems, drive tapes, and timing belts share unique qualities that make them ideal for a versatile range of automation and robotic systems applications. By participating in international trade show exhibitions, Belt Technologies engineers are able to demonstrate the benefits of metal belts and give advice to potential clients on a global scale.

Would your automation or robotics system benefit from the precision and cleanliness of stainless steel belts and drive tapes? Contact the experts at Belt Technologies today.

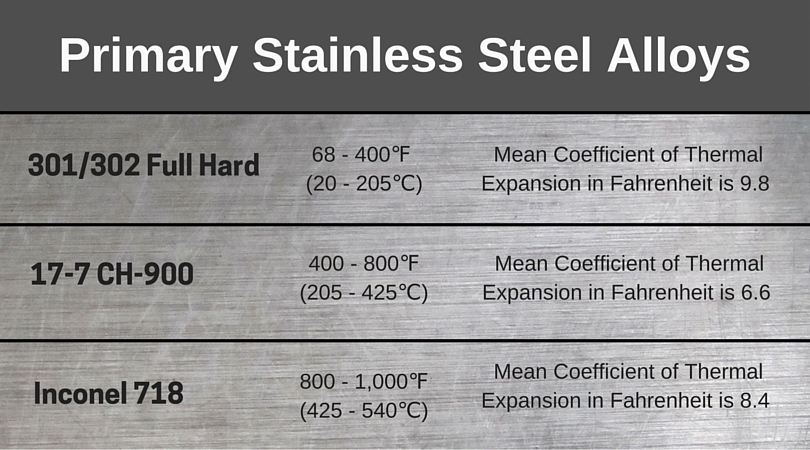

In addition to inherent corrosion resistance, metal belts withstand high- and low-temperature operating environments that rubber, plastic, or fabric belts cannot. The temperature-resistant qualities of metal belts are advantageous in heated applications such as

In addition to inherent corrosion resistance, metal belts withstand high- and low-temperature operating environments that rubber, plastic, or fabric belts cannot. The temperature-resistant qualities of metal belts are advantageous in heated applications such as

anodization. Each surface treatment and coating option exhibits unique characteristics, including thermal resistance, impact and abrasion resistance, nonstick release, and FDA approval for use in food processing and pharmaceutical applications.

anodization. Each surface treatment and coating option exhibits unique characteristics, including thermal resistance, impact and abrasion resistance, nonstick release, and FDA approval for use in food processing and pharmaceutical applications.  cure, nonstick surface and up to ten times the abrasion resistance of Teflon.

cure, nonstick surface and up to ten times the abrasion resistance of Teflon.

shortens the lifespan of the belts and costs manufacturers time and money in product volume loss each time the belts have to be replaced.

shortens the lifespan of the belts and costs manufacturers time and money in product volume loss each time the belts have to be replaced.