When you hear the word “unlimited,” what comes to mind? It’s a word that gets used a lot, but when you really think about what it means, it can be difficult to conceptualize.

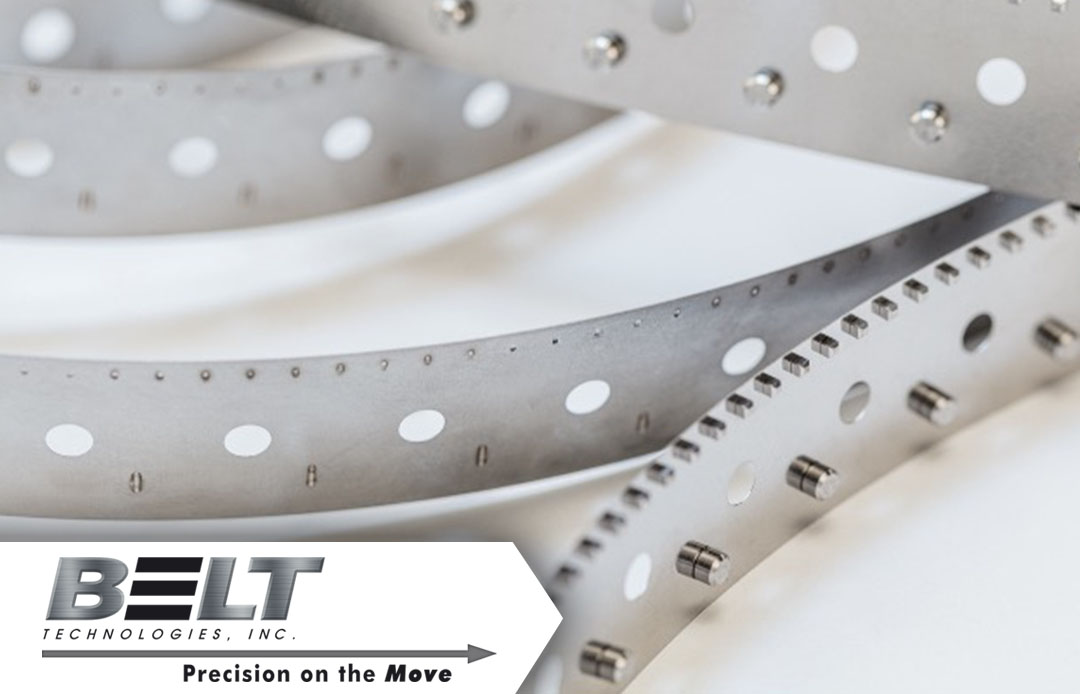

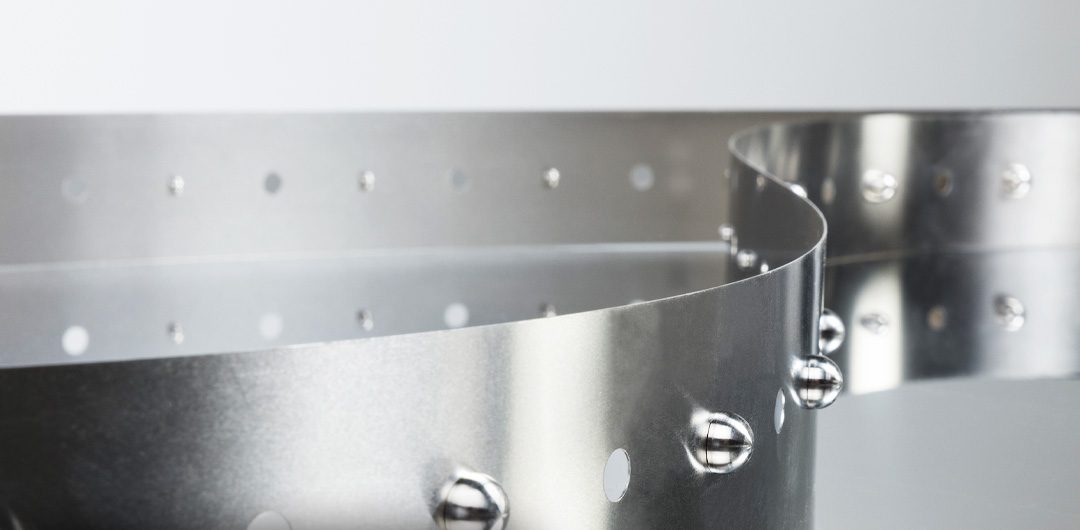

According to the Oxford Dictionary, the definition of unlimited is “not limited or restricted in terms of number, quantity or extent.” A tall order, to be sure, but one that Belt Technologies can fulfill when it comes to our perforated PureSteel® belts. By implementing a variety of methods to perforate metal, we are capable of creating belts with virtually unlimited number of custom perforations, in a virtually unlimited number of shapes and sizes, providing our customers with boundless precision and customization options. In this blog, we explain how these customization options can help you achieve your production goals.

Why Perforated Belts?

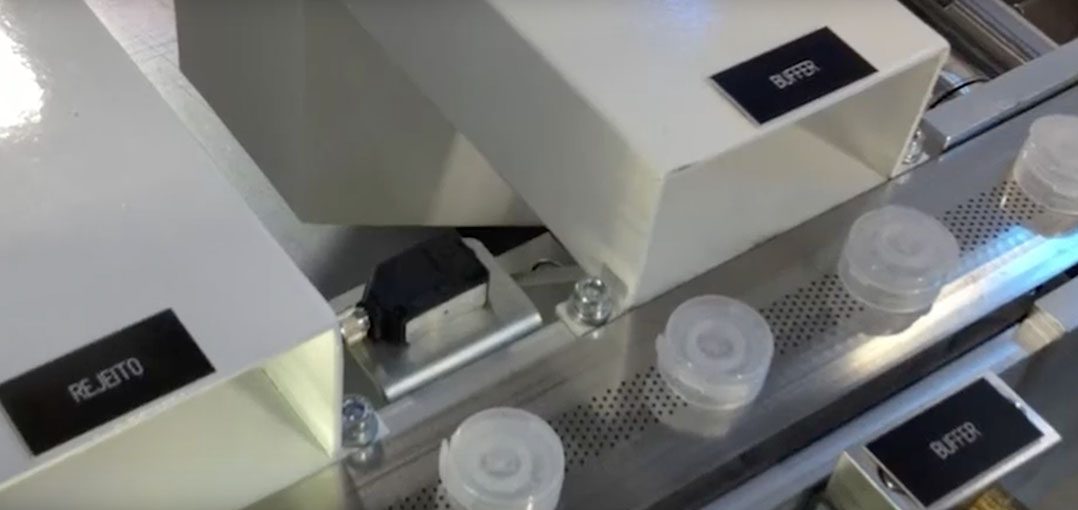

Due to their advantages in vacuum conveying (to securely hold products in place), perforated belts are often leveraged by companies requiring precision indexing. This need isn’t limited to a single industry, so we don’t limit the perforations to a particular product or product line.

We have successfully implemented design cut-outs into both timing belts and vacuum conveyors. Whether these perforations are needed for indexing, machine automation, positional accuracy or other requirements, we can deliver solutions for the following applications:

- Solar panel production

- Printing

- Packaging

- Clean rooms

- Electronics manufacturing

- Pharmaceutical processing

Perforation Methods and Techniques

Our team understands the many factors that must be considered when selecting a perforated metal conveyor belt to optimize its performance and durability for a specific application. For this reason, we employ three separate methods to create the perforations in our PureSteel® belts, including stamping, laser cutting, and chemical etching.

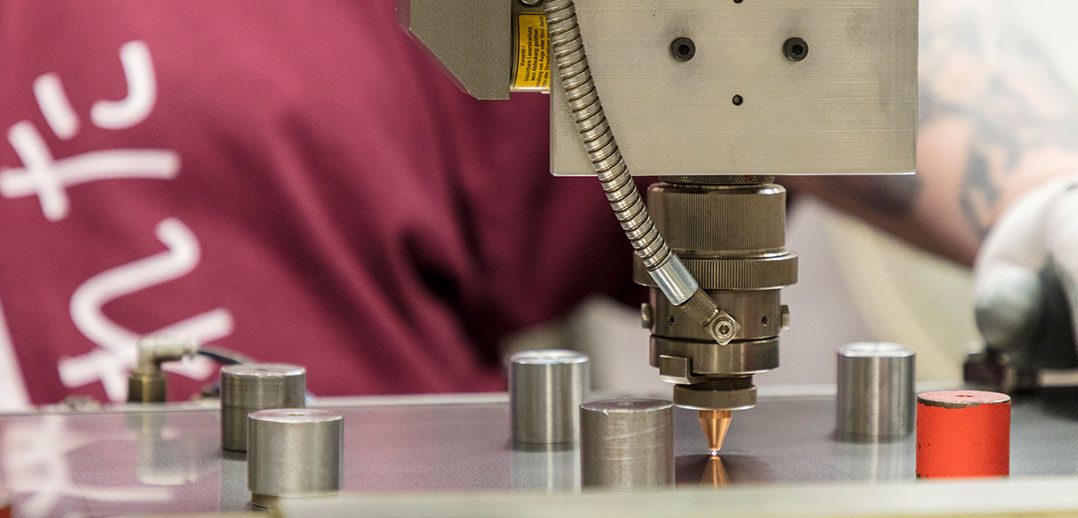

Our in-house laser cutting services and perforation techniques produce consistent, accurate and precise perforations with no burr. We can perforate belts as thin as 0.002” (0.051 mm) or as thick as 0.031” (0.78 mm), and belts narrow as 0.125” (3.175 mm) or as wide as 36” (900 mm).

A Pitch-Perfect Example in the Medical Field

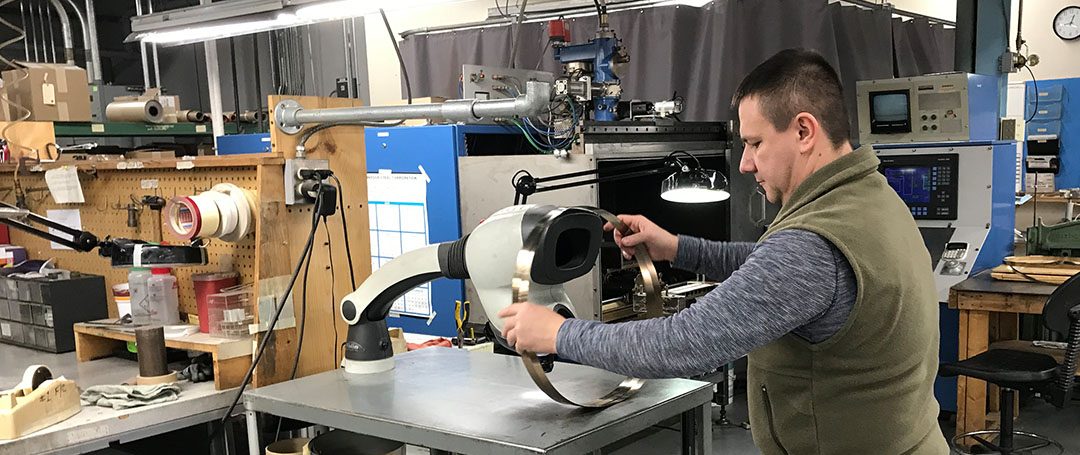

Let’s look at a real-world example. Two of the most important factors in medical manufacturing are accuracy and cleanroom capability. When the Arthur G. Russell Company (AGR), a medical equipment manufacturer based in Connecticut, required a metal belt with a pitch profile (perforation pattern) that didn’t currently exist, they turned to us.

AGR required a conveying solution for a new medical device assembly machine that moves small needles for automated assembly, so a precisely designed custom belt was necessary. Our product had to excel in a cleanroom environment while offering repeatability and the personalization of a custom pitch. We worked alongside their team to create a custom belt that met their exact specifications. This solution, which was created for the machine in 1998, is still in use today.

Develop Your Custom Solution Today

Our virtually unlimited array of perforations is just one of many reasons to partner with Belt Technologies. Our team has perfected the engineering of every aspect of our PureSteel® belts, so you can trust us to design a unique belt to meet your exact needs. Contact us to learn more.

Due to their unique physical properties, fine powders and other bulk solids can be some of the most

Due to their unique physical properties, fine powders and other bulk solids can be some of the most

As the effects of climate change continue to impact the world in increasingly negative ways, people across the United States have decided to take the initiative to lower their personal carbon footprint into their own hands. In fact, according to the

As the effects of climate change continue to impact the world in increasingly negative ways, people across the United States have decided to take the initiative to lower their personal carbon footprint into their own hands. In fact, according to the

The most noteworthy inventions throughout history provide a simple solution to a problem or an indispensable benefit to the user. Think Johannes Gutenberg and the printing press or Alexander Graham Bell and the telephone. At Belt Technologies, every

The most noteworthy inventions throughout history provide a simple solution to a problem or an indispensable benefit to the user. Think Johannes Gutenberg and the printing press or Alexander Graham Bell and the telephone. At Belt Technologies, every

When it comes to conveying, suction is an ideal method for keeping small, lightweight parts in place—but how does it work on a production line? Our

When it comes to conveying, suction is an ideal method for keeping small, lightweight parts in place—but how does it work on a production line? Our