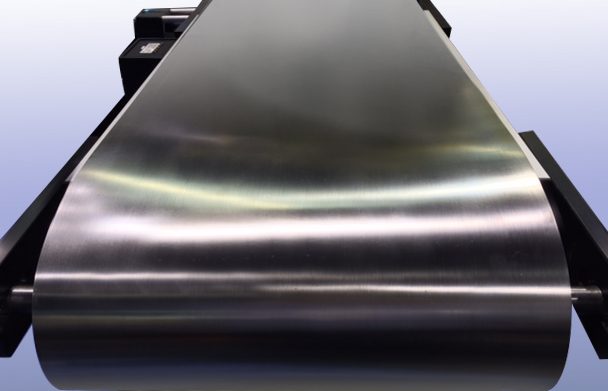

Our engineering team recently took on a project for a medical manufacturing application. The customer would be assembling an automated conveyor system for the production of medical adhesive. They were seeking a conveyor belt material that would be able to transport the thin plastic film through the adhesive-curing process.

Heat Curing Adhesive onto Plastic Film

To produce the medical adhesive, a thin plastic film is laid on the conveyor belt. It is then sprayed with an even coat of adhesive material. The coated plastic is then transported through a heating process to cure the adhesive.

The client required a conveyor belt with limited deviation in thickness and the ability to transport the plastic film quickly and accurately. Because this was a medical application, the belt needed to be extremely clean to operate in order to prevent particulates or foreign particles from adhering to or contaminating the adhesive. Curing the adhesive to the plastic film requires the belt material to be able to withstand temperatures around 200°F continuously.

Highly Hygienic Stainless Steel Is Perfect for Medical Applications

Stainless steel is an ideal choice for medical and pharmaceutical applications due to its unique physical properties. The smooth, impermeable surface of a stainless steel conveyor belt is highly resistant to bacteria and it does not require lubrication to operate. Additionally, metal conveyor belts do not outgas or generate particulates, which minimizes any risk of contamination to medical products being transported. A high resistance to corrosion enables stainless steel belts to withstand virtually any cleaning method, including high-pressure wash, chemical cleansers, and high-pressure steam.

The properties of stainless steel also include a high resistance to temperature extremes. While there are many different grades of stainless steel—each able to withstand a specific range of temperatures—nearly all varieties are capable of operating in the temperatures specified by this customer.

Achieve Smooth, Reliable Operations with Metal Belt Conveyors

Belt Technologies engineers provided the customer with a solid, stainless steel conveyor belt with no deviation in thickness that would provide accurate, repeatable results. The clean, sanitary surface of the belt and the high temperature resistance of stainless steel ensures the medical adhesive will be able to cure quickly and cleanly with very little risk of contamination.

For custom metal conveyor belt solutions to automation challenges, contact the experts at Belt Technologies, Inc.