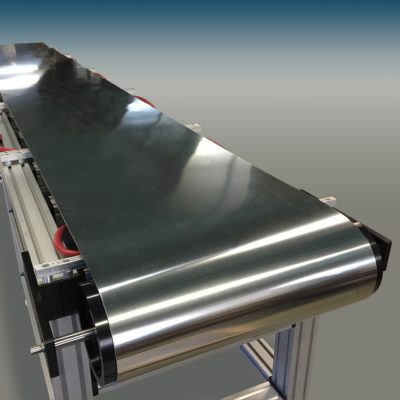

Add a Coating to Your Belt for Improved Performance

Coatings alter the surface properties of custom coated metal belts and tapes, optimizing their performance across applications. Our engineers can work with virtually unlimited surface coatings, including:

• Teflon®

• Neoprene

• Polyurethane

• Silicone

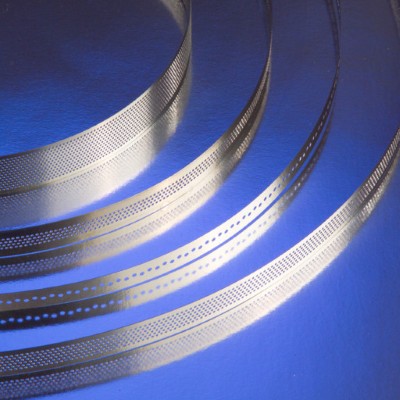

These specialized surface treatments can be applied to one or both sides of a PureSteel® custom coated metal belt or tape via coating, plating, laminating or bonding methods. Depending on the application, the surface treatment can be as thin as 0.0005 inch (.0125 mm).

Benefits of Metal Belt Surface Treatments

The benefits of surface coatings vary based on the type of coating applied. Some common advantages include:

• Non-stick qualities

• Improved lubricity

• Increased friction

• Corrosion resistance

Certain coatings, such as polyurethane, neoprene and silicone, can create pockets on the belt’s surface to hold small components during transport. Belt Technologies has the ability to provide these coatings with specific die-cut pocket geometry that can also be combined with vacuum perforations for more positive orientation and retention of small or delicate parts during transport.

Common Applications

A variety of industries benefit from custom coated metal belts. For example, food processing, heat sealing bands in the packaging industry and high-temperature manufacturing environments benefit from Teflon®. Silicone or neoprene provide a higher friction surface that aids in maintaining part orientation during belt movement. They will also increase the friction coefficient of a metal belt, tape or pulley to overcome slipping issues and allow the belt to run at a lower tension.

From common coatings to specialized surface treatments, our engineers are happy to guide you in choosing the ideal coating for your application. Contact us to get started.

Explore Our PureSteel® Metal Belts:

Endless Belts

Learn About Endless Belts

Wide Belts

Learn About Wide Belts

Perforated Belts

Learn About Perforated Belts