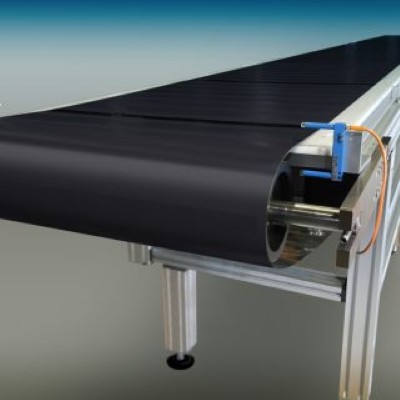

Strength and versatility for even the most demanding environments

Optimize automated operations with the strength and versatility of seamless PureSteel® endless metal belts are terminated by welding the ends of the steel belt using electron beam or laser technologies This advanced process forms a high-integrity butt weld that is strong, smooth, and distortion-free, ensuring seamless performance in even the most demanding applications.

High-Precision Welding for Stainless Steel Conveyor Belts

Our Proprietary Welding Method Creates Strong, Reliable Welds

Belt Technologies uses proprietary welding methods to create a strong, endless joint that is essentially seamless. The precision joint is created with either laser, electron beam or plasma equipment using processes developed to ensure the weld joint is smooth and distortion free. Our experienced staff of engineers determines the appropriate welding method based on material and application requirements.

Our welds are high strength and able to withstand harsh environments, whether it’s temperature, chemical or ultra-high vacuum systems. Our PureSteel® endless steel conveyor belts are used for virtually any application imaginable, in fields as diverse as aerospace, robotics, food processing, medical, industrial automation, semiconductors and more.

High-Energy Beam Welding

Belt Technologies utilizes proprietary welding processes that create a strong, distortion-free weld. Weld finishing techniques can be applied to the weld joint to create a seamless surface that mimics the surface of the belt.

Explore Our PureSteel® Metal Belts

Wide Belts

Learn About Wide Belts

Coated Belts

Learn About Coated Belts

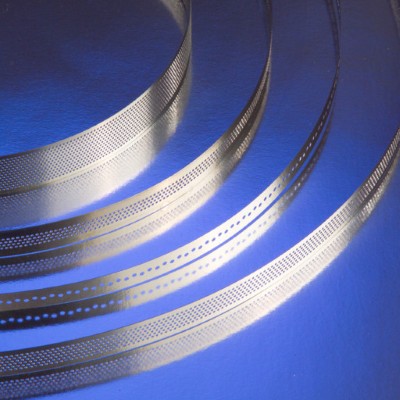

Perforated Belts

Learn About Perforated Belts