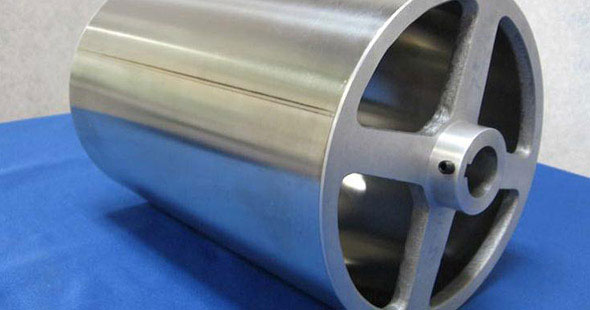

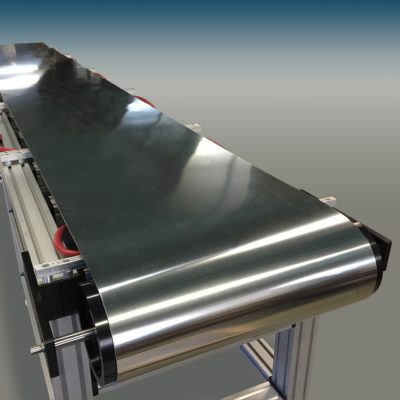

Friction drive pulleys are generally constructed of solid roundstock, I-beam or tube and cap designs. A flat face is preferred on any of these designs to optimize belt life. A crowned face or narrow width can be considered to assist in belt tracking, but both designs will reduce the belt life. A Belt Technologies Sales Engineer can assist in determining the appropriate tracking method depending on the application.

Full Radius Crown

If a full radiused crown is the most appropriate method of belt tracking, the radius should not exceed the thickness of the steel belt. Premature belt failure can occur when high loads are applied to the belt, resulting in the belt cracking down its centerline.

Trapezoidal Crown

If a trapezoidal face design is deemed the most appropriate method of belt tracking, the contact area of the pulley face should be specified to 75% of the belt width. This method of tracking will generate less detrimental stresses on the steel belt, as compared to a full-face crown design.

Other Considerations

A narrow bodied roll is very similar in concept to the trapezoidal crown. The overall pulley width is reduced to 75% of the belt width. This simulates a crowned face using the two edges of the pulley to assist in belt tracking.

Interested in Learning More about Friction Drive Pulleys?

Contact Belt Technologies to discuss how friction drive pulleys and metal pulleys can benefit your system.

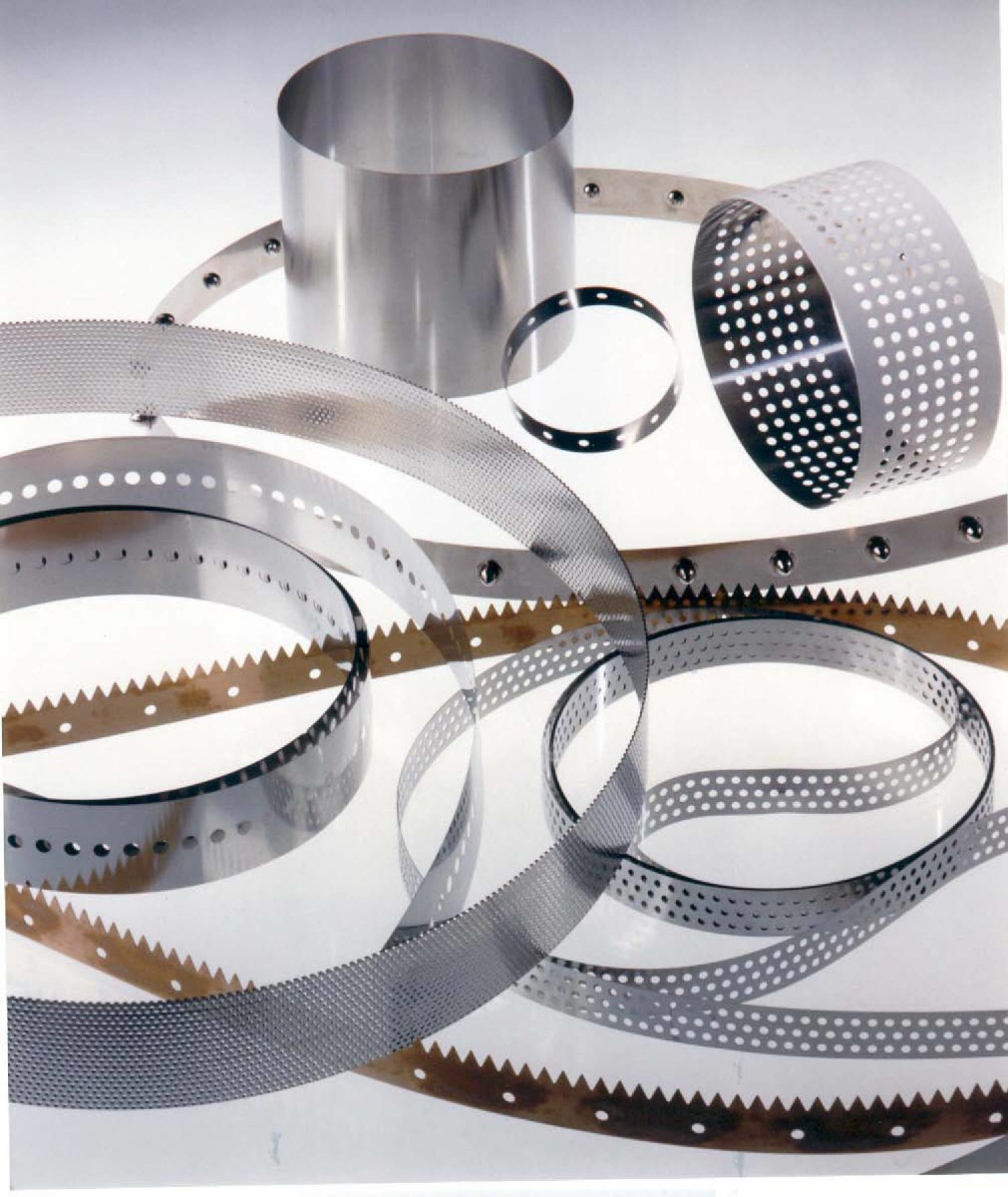

Explore Our PureSteel® Metal Belts:

Endless Belts

Learn About Endless Belts

Wide Belts

Learn About Wide Belts

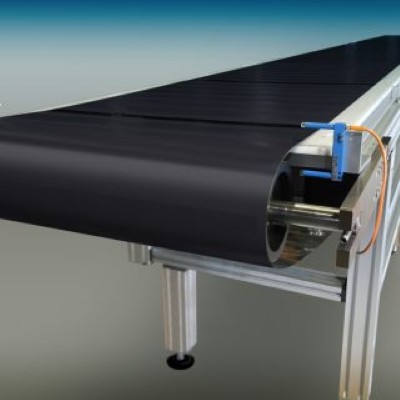

Coated Belts

Learn About Coated Belts