Field Termination

PureSteel® endless stainless steel belts work in most every application and industry. In some applications, an endless belt is not feasible to install on the conveyor system. To overcome this obstacle, we offer several options that can terminate the belt on the machine.

Overlap Termination

The first option is an overlap termination. The belt ends are overlapped and fastened together using rivets or screws.

Piano Hinge

Piano hinges also create a termination point. We’ll supply the belt with a welded continuous hinge on each end that can be terminated on site by pinning the ends together.

On-Site Welding

Belt Technologies offers on-site welding services. We’ll travel to your location with our custom tooling and weld the belt endless on your machine. Please consult your design engineer to see if one of these options will work for your application.

Tracking Solutions

We can help with the standard steel belt conveyor design to optimize tracking solutions of your PureSteel® metal belt or conveyor system. Belt Technologies can also help with engineered forced tracking solutions such as Metrak©, Flanges or Cam followers.

Independently Steerable Pulley (ISP)

Belt Technologies has developed a simple and effective pulley system for independently steering flat belts while allowing for easy, on-the-fly tracking adjustments.

This patented system solves tracking problems that result from changes in an operating environment; it also eliminates downtime by allowing independent belt adjustments on a common, multi-pulley shaft. Steering is accomplished by adjusting the angle of the pulley relative to the belt and modifying lateral tension. Rather than moving the pulley shaft through the use of pillow block adjustments, the ISP design fits a variable steering collar (with either a skewed or offset bore) and a sealed bearing assembly to the body of the pulley. When rotated, the collar changes the angle of the pulley body, resulting in the controlled bidirectional movement of the belt across the pulley face.

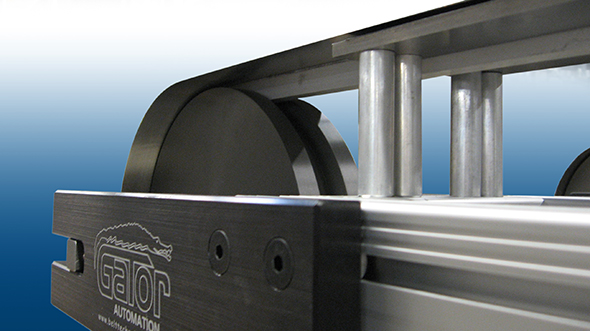

TruTrack™ Pulley System

The TruTrack™ Pulley system is another simple and effective forced tracking solution that monitors and regulates the tracking of a metal belt. It incorporates a frictionless, segmented roller design with cam followers acting as edge guides. The segmented design substantially reduces side loads on the belt, preventing edge damage and increasing the belt’s overall lifespan.

The versatile TruTrack™ can be used in multiple industries and applications and comes as a standalone product or as part of a conveyor system designed by our engineers.

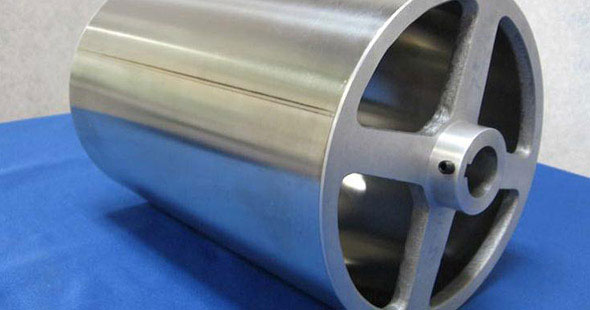

Crowing Friction Drive Pulleys

When crowned friction drive pulleys must be used, it is in conjunction with—not in place of—axis adjustment. This is because crowned pulleys will not self-center a metal belt. Crowned pulleys work best on thin belts, as the belt web must conform to the crowned face of the pulley. While increased tension can be used to achieve belt-to-pulley face conformity, tension cannot be so high as to cause permanent belt deformation. The optimal geometry for a crowned friction drive pulley is a full radius, with a chord height no greater than the thickness of the belt that is running on the pulley.

Pulley Axis Adjustment

Adjusting the pulley axis in a metal belt system is the most effective way of tracking a metal belt. Belt edge tensions are changed in a controlled manner, thus steering the belt. This technique applies to all pulley types. Ideally, both the drive and idler pulleys would have adjustable axes. In reality, however, the idler is the only adjustable pulley. The drive pulley is usually difficult to adjust due to its interface with motors or other power transmission devices.

Forced Tracking

We often refer to forced tracking as a method for maintaining lateral positioning of a steel belt. In this video, Belt Technologies President Al Wosky demonstrates the use of cam followers as a method of forced tracking. The steel belt edge rides on the bearings’ surface, or cam follower, to achieve belt tracking and lateral position. This method of tracking can achieve an accuracy of better than 0.001”!

In cases where simple axis adjustment cannot completely eliminate improper tracking, forced tracking methods such as cam followers or glass-filled Teflon® flanges may be necessary and acceptable. System design relationships may need to change; this may involve the use of a thicker belt than might otherwise be recommended, since forced tracking techniques can contribute to a decrease in expected belt life.

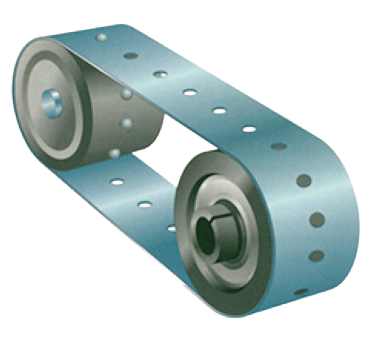

Metrak© Tracking

An alternative forced tracking technique for wider belts employs a V-belt bonded to the inner circumference of the metal belt. This two-element belt, which Belt Technologies calls the Metrak© System, distributes tracking stresses on the V-belt, forcing the steel belt to run true regardless of any other tracking influences.

Everything We Manufacture Is Custom

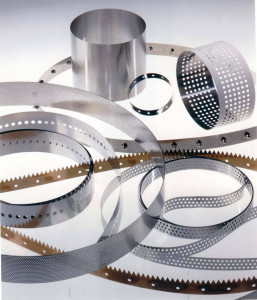

We manufacture PureSteel® belts ranging in width from 0.040” up to 35” wide and thicknesses of 0.001” up to 0.035” thick. We have the ability to manufacture a specific width and thickness combination based on the requirements of the application.

Everything we manufacture is custom, which also includes coatings, attachments and perforation patterns. Tell us what you need, and we’ll be happy to deliver it. We work with all different industries and design specific widths or thicknesses of customized turnkey solutions for businesses within each.

Contact us with your technical requirements or to discuss your automated manufacturing process and we’ll design a product for your unique application.