Belt Technologies was recently approached by a customer that produces plastic pellets for recreational and automotive components. The pellets were made by extruding hot, melted plastic onto a conveyor belt which would then be transported to the next production phase while it cooled.

The original conveyor system used a basic mesh metal belt to transport the resin pellets after they were extruded. Unfortunately, the surface texture of the mesh metal belt was leaving undesired impressions on the plastic as it cooled. The customer came to the experts at Belt Technologies seeking a solution that could improve their system’s product handling.

Replacing Mesh Metal Conveyor Belts

The customer wanted proof of concept before investing in an entirely new conveyor, so they designed a belt that could be retrofitted to their existing conveyor system. Belt Technologies has experience with these types of customer requests, and we were able to advise them that replacing the belt would be a satisfactory solution to their problem. Our team visited the customer at their facility to survey the system and ensure that a replacement conveyor belt would be possible. To replace the mesh metal belt, our experts determined the original pulleys were too small and would need to be replaced with drive pulleys. In addition, due to the restricted size of the system, the new belt would need to be welded in place, rather than being welded first and installed after the fact.

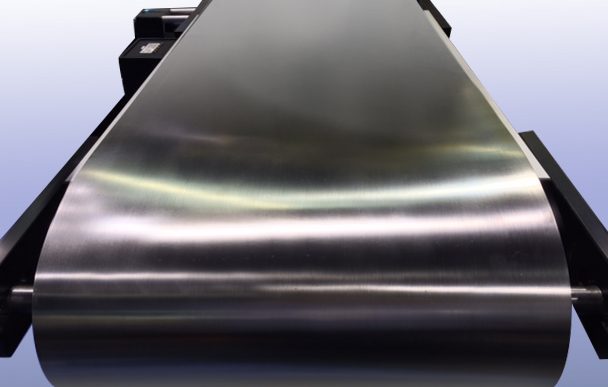

The plastic would be extruded onto the belt at temperatures ranging from 500°F to 600°F. The new belt would need to be able to withstand these elevated temperatures. The unique properties of stainless steel make our endless metal conveyor belts an ideal choice for applications dealing with high heat. They are resistant to extremes in temperature and will not warp, even with continuous exposure, enabling them to last much longer than conventional conveyor belt materials.

Achieve Superior Product Quality and Throughput

Endless metal conveyor belts from Belt Technologies have a flat, impermeable surface which makes them the best option for applications that need a smooth product finish. They are made from a flat sheet of stainless steel, rather than a series of links and chains like mesh metal belts. We produce endless metal belts by welding stainless steel into a continuous band. Our welds are seamless and incredibly strong—achieving flawless welds when working with thin stainless steel belts is our specialty.

To install the new replacement belt, it would need to be welded in place on the existing system. Our team has the ability to weld belts onsite if necessary, however, the customer was willing to send their entire system to Belt Technologies to complete the installation. With the new, smooth metal belt from Belt Technologies successfully installed, the customer was able to achieve the perfect product results they were looking for.

To find out more about how endless stainless steel belts can improve your product handling, contact the experts at Belt Technologies today.