A producer of PVC plastic recently approached Belt Technologies with a problem. They had been beta testing belt materials for their conveyor system and had not yet found a solution that would work. They needed a conveyor belt that could transport hot PVC plastic without leaving any marks on the surface of the plastic as it cooled. The silicone belt they had been testing was not working due to a seam in the belt that left a mark on the product when it cooled.

A producer of PVC plastic recently approached Belt Technologies with a problem. They had been beta testing belt materials for their conveyor system and had not yet found a solution that would work. They needed a conveyor belt that could transport hot PVC plastic without leaving any marks on the surface of the plastic as it cooled. The silicone belt they had been testing was not working due to a seam in the belt that left a mark on the product when it cooled.

A Special Application: Extruding PVC Plastic

The customer was searching for a belt that would not leave impressions on the product they were extruding. The customer needed to extrude PVC plastic that was 1/2” wide and 1/8” thick onto a belt and then allow it to remain on the belt while cooling. The PVC plastic would be extruded at temperatures of 350°F to 400°F, so the belt needed to withstand these high temperatures.

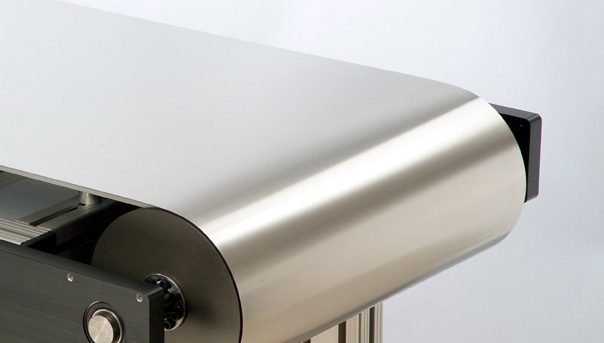

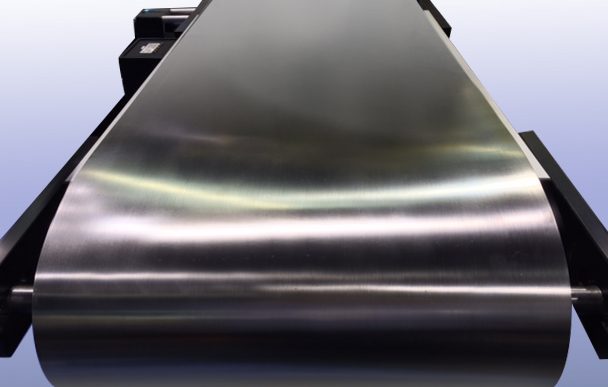

Stainless steel metal conveyor belts have a high resistance to temperature, which make them a great choice for this type of application. Most importantly, the smooth surface of an endless metal belt allows hot plastic to cool without leaving any impressions in the PVC, thus preventing unnecessary damage to the product.

Choose Endless Metal Belts for a Smooth Product Finish

Endless metal belts deliver the ideal combination of precision, strength, and versatility. We manufacture metal belts by welding stainless steel into endless belts. Our welds are incredibly strong and can be weld-finished for better blending. Achieving flawless results when welding thin stainless steel belts is our specialty. With the endless metal belt from Belt Technologies, the customer was able to achieve the smooth product results they desired while maximizing product output and speed.

Optimum Results with Custom Coatings for Your Application

This customer wanted to prevent the hot plastic from adhering to the belt as it cooled, so we added a Teflon coating to the Belt. Belt Technologies offers various Teflon coatings with benefits including food-grade qualification, abrasion resistance, and chemical resistance. For this customer, we chose a Teflon with good release characteristics to make sure the product would not stick to the belt.

Belt Technologies has the ability to design and manufacture custom metal conveyor belts for virtually any application. Surface coatings and surface treatments help expand the potential uses for stainless steel metal belts. BTI provides several options, including Teflon, silicone, polyurethane, and more.

Looking to increase the efficiency of your conveyor system and get better product results every time? Call or request a quote today!