At Belt Technologies, we are dedicated to the success of your system. Our engineers are always willing to aid customers who may experience issues with their metal conveyor belt systems, including traveling onsite to customer locations to observe issues in the field and work with your team to find actionable solutions. Recently, a customer contacted us to get help figuring out why the metal belts in their dual belt conveyor system were routinely wearing out.

Trouble with Excessive Wear in Parallel Conveyors

An OEM in the medical manufacturing industry was having trouble with a pair of metal belts aligned side by side in a system designed to transport tooling for dental aligners through a packaging process. Unfortunately, the flanges on the belts and some of the timing attachments on the belts were cracking and wearing down much faster than the design specified. They called Belt Technologies to see if the experts on our team could help them achieve a longer lifespan for their conveyor belts.

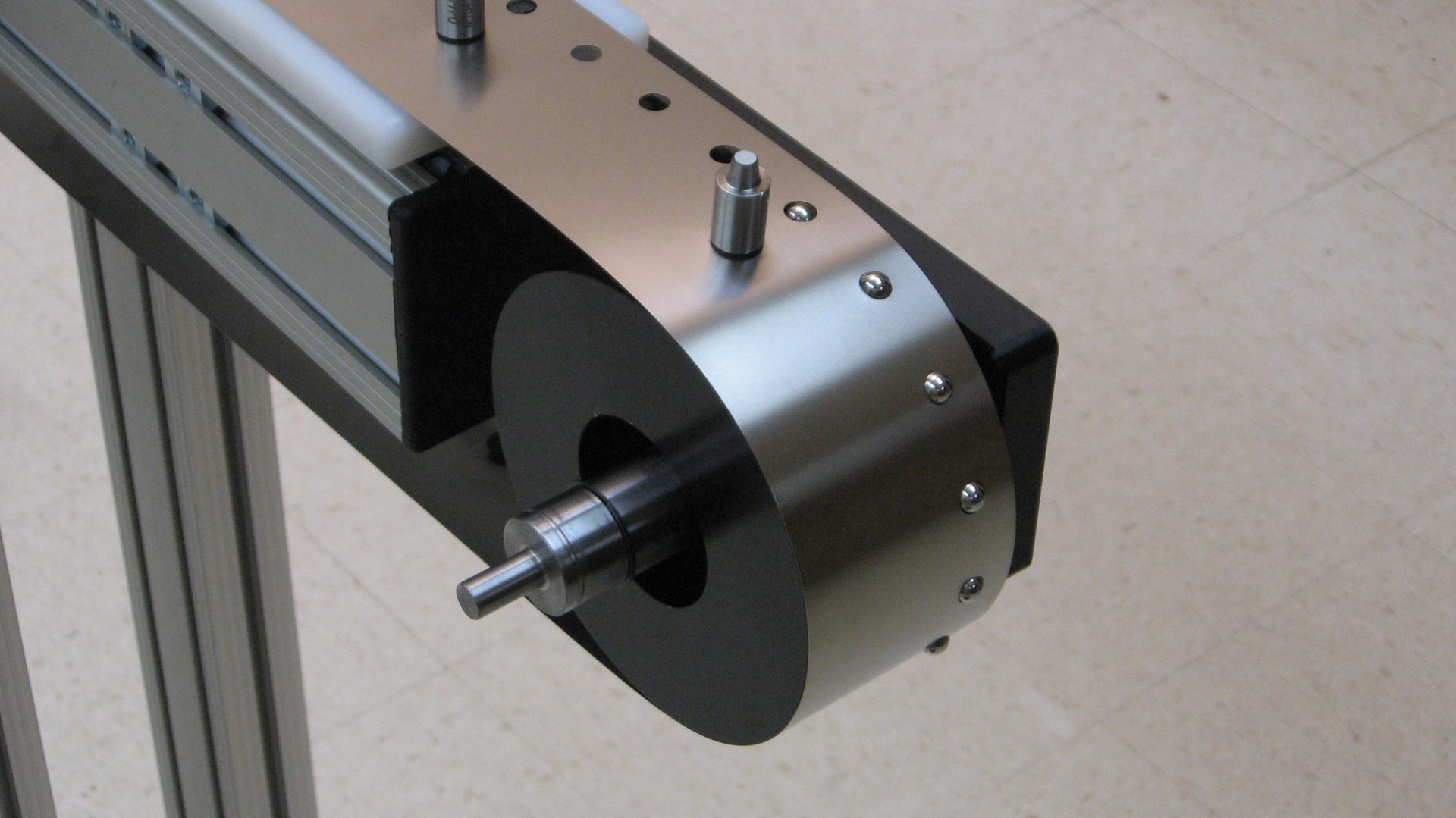

For this system, the belts were arranged in parallel on a common drive shaft with independent tensioning on the idler side. Both pulleys included relief grooves in the face for clearance of a screw head for fixed attachments on the belt. To keep the tracking of the two belts in sync, the drive pulley was a specially designed timing pulley. The idler pulley included flanges, which also kept the belts in alignment to ensure proper product positioning. The customer initially suspected the flanges of causing the excessive wear, as they were visibly damaged over time while the belts were in use.

When Installing a Metal Belt, Proper Tensioning is Key

Technical support traveled to the customer site to assist in the troubleshooting. Our team spoke to their maintenance and engineering staff and observed the equipment in operation. After examining the system in use, our engineers were able to determine that the flanges were not the cause of the wear and tear.

The customer was installing the belt with a very high tension that created excessive friction between the belt and pulley. As a result, the belt was not realigning with the timing pins on the drive pulley. Consequently, the timing holes cracked when the belt was forced over the timing pins by the sizeable frictional load. Once the belt was forced out of position with the timing teeth, the flanges on the pulley were damaged by the edge of the belt. Belt engineers worked with the on-site staff to develop a repeatable method to tension the belt within the correct range and to train them on how to correctly install and tension the belt.

When installing a stainless steel conveyor belt, proper tensioning is key to ensuring optimal performance and the longevity of the system. Adjusting the tension varies based on the belt type. For more information, or if you suspect your conveyor is experiencing belt tension issues, contact the experts at Belt Technologies today.

Belt Technologies has the capability to produce custom stainless steel belts for a variety of unique applications beyond conveyor belt systems. One such application includes an automated pill dispenser cabinet for a large, medical device OEM. The dispenser for these projects is designed with a series of drawers that house medications for secure storage. To ensure the prescription pills cannot be dispensed without proper authorization, each drawer is built with a unique metal belt made with specialized window perforations. These window perforations limit access to the medications in the drawer. Only the necessary dosage is reachable through the window.

Belt Technologies has the capability to produce custom stainless steel belts for a variety of unique applications beyond conveyor belt systems. One such application includes an automated pill dispenser cabinet for a large, medical device OEM. The dispenser for these projects is designed with a series of drawers that house medications for secure storage. To ensure the prescription pills cannot be dispensed without proper authorization, each drawer is built with a unique metal belt made with specialized window perforations. These window perforations limit access to the medications in the drawer. Only the necessary dosage is reachable through the window.