Belt Technologies, Inc. has been contacted by several customers specializing in manufacturing advanced vacuum deposition equipment. The machinery they develop is typically used to deposit micrometer- to nanometer-thin, functional coatings on materials such as glass, metal strips, wafers, and polymer films. These materials are typically used in products like solar panels, architectural glass, and smartphone displays.

Designing a Conveyor Belt for Micrometer and Nanometer Vapor Deposition

For this particular application, the customers usually seek a series of belts, pulleys, and timing elements. The belts are to be run in pairs, carrying a product to a high-vacuum chamber for a vapor deposition process.

Vapor deposition is a precise process used to coat products with a layer of material. These coatings are often extremely thin; the vapor deposition process can be used to deposit the material atom-by-atom or molecule-by-molecule. It is typically used for coating exceptionally sensitive materials and equipment. To be successful, the vapor deposition process requires a high-vacuum environment with zero risk of contamination.

No Room for Error: Stainless Steel Is Clean, Precise and Reliable

Once the material reaches the vacuum chamber and the chamber is closed, there is no room for adjustment if the belt tracks off course or the material shifts in transit. Therefore, it is necessary that the motion profile of the belt be reliably precise. The belts also have to be exceptionally clean in order to prevent contamination. Anything that could potentially cause a delay in production, such as belt realignment, maintenance, or decontamination would cost up to several thousand dollars an hour in lost production time.

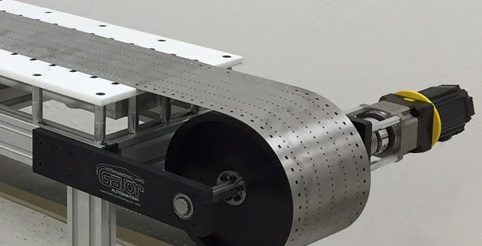

Stainless steel is an ideal material choice for applications requiring cleanliness and accuracy. Metal belts made of stainless steel do not require lubrication, do not outgas, and do not generate particulates. They are excellent for clean room applications and high-vacuum environments. To ensure the product would be transported safely and would not slip on the belt, our team added attachments to the belt design.

Timing Elements Ensure Accurate, Repeatable Results

The customer’s equipment design requires a timing element to keep production running smoothly. Our team provides the client with metal conveyor belts fitted with custom attachments to keep the product in place; we also use timing pulleys to provide maximum accuracy. The timing pulleys are configured with specially designed evacuation holes around each timing element. This prevents air from getting trapped behind the timing ball and helps to avoid any interruption to the vacuum conditions inside the chamber.

The engineers at Belt Technologies, Inc. have the knowledge and capability to provide custom stainless steel conveyor belt solutions for virtually any application. Contact us today and find out how metal belts can improve your automated conveyor system.