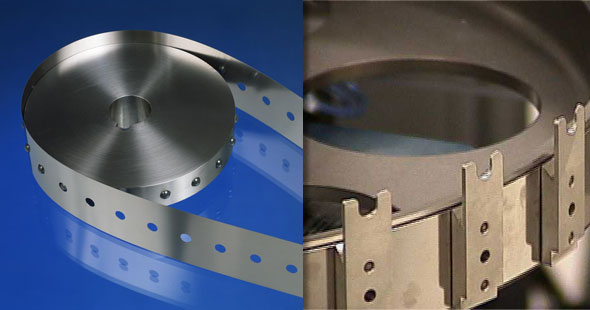

Stainless steel conveyor belts, timing belts, and drive tapes can be found in some of the most innovative automation technologies of our time. The versatility and durability of stainless steel make it an ideal material choice for a variety of industries. Belts and drive tapes made of stainless steel are easily customized to suit a wide range of operating conditions and handling requirements. They can endure extreme temperatures, heavy loads, and even caustic chemicals without warping, breaking, or losing positional accuracy. These characteristics give stainless steel drive tapes, timing belts, and conveyor belts the advantage when it comes to cutting-edge automation technology.

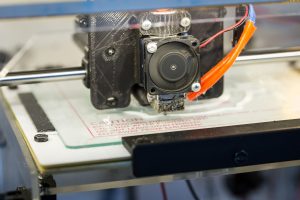

Expanding 3D-Printing Applications

3D-printing technology is rapidly becoming a mainstay in the world of manufacturing. 3D printers now exist in many sizes and capabilities; they range from smaller, desktop models designed for use at home to huge, industrial models capable of fabricating complex equipment such as bridges and boats. Belt Technologies engineers have provided 3D printer OEMs with design feedback and support as well as the stainless steel printing belts and drive tapes that make it all possible.

3D-printing technology is rapidly becoming a mainstay in the world of manufacturing. 3D printers now exist in many sizes and capabilities; they range from smaller, desktop models designed for use at home to huge, industrial models capable of fabricating complex equipment such as bridges and boats. Belt Technologies engineers have provided 3D printer OEMs with design feedback and support as well as the stainless steel printing belts and drive tapes that make it all possible.

Our team has worked on a variety of 3D-printing projects that push the boundaries of this burgeoning industry. For example, one manufacturer was working on a design for a portable, desktop model of a 3D printer. Belt Technologies designed and produced for the customer a miniaturized printing belt that included tiny pulleys. Creating a functioning printer head and belt at such a small scale was a unique challenge that our team was happy to meet head-on.

Belt Technologies has helped with the design and production of very large 3D printers, too. One recent customer required belts for massive machines intended for the production of industrial equipment. Instead of a printer head that moved side to side as it lays down material, these specific 3D printers were designed to use a belt that moves the printed object around a nearly stationary printer head. The size of the objects being printed put a heavy frictional load on the belt; inferior belt materials damaged too easily and would not last very long. Belt Technologies engineers provided the customer with a solid, stainless steel belt with a friction-reducing coating on the interior diameter to help extend the belt’s lifespan and maximize product throughput.

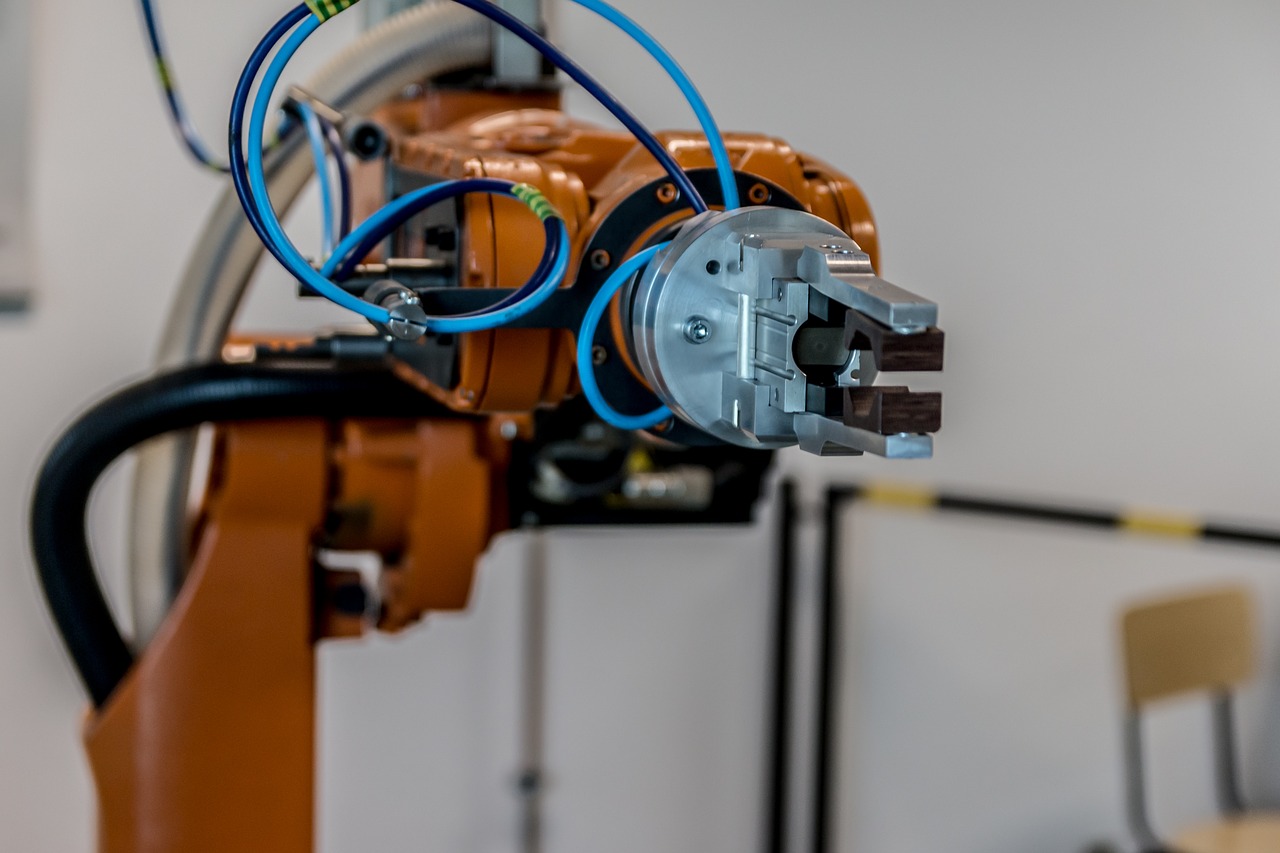

Robotics Applications Benefit from the Strength and Precision of Stainless Steel

When we think of “futuristic technologies,” robots are probably one of the first things to come to mind. Although science is still a long way from creating the kind of robots we might be accustomed to seeing in science fiction, there are many industries that use robotics as part of their everyday operation. Robotic assembly lines are a common automation tool that make it possible to produce sensitive electronics, medical equipment, and other products that require absolute precision.

When we think of “futuristic technologies,” robots are probably one of the first things to come to mind. Although science is still a long way from creating the kind of robots we might be accustomed to seeing in science fiction, there are many industries that use robotics as part of their everyday operation. Robotic assembly lines are a common automation tool that make it possible to produce sensitive electronics, medical equipment, and other products that require absolute precision.

Belt Technologies engineers have worked with multiple robotic automation OEMs to design and produce equipment for the safe handling of products such as semiconductor wafers and vaccines. Stainless steel drive tapes are ideal for these applications. They are virtually non-stretchable and able to provide repeatable, precise motion profiles. Robotic arms with stainless steel drive tapes can perform an action thousands of times, with no change in the range of motion per cycle. They are also easy to clean, do not require lubrication, and do not generate particulates, making them ideal for kind of sterile environments such as in clean rooms and vacuum spaces, where robotics technologies are generally needed.

Do you have a new, innovative automation challenge that would benefit from the unique properties of stainless steel? Contact the experts at Belt Technologies today to learn more.