Custom timing pulleys designed and manufactured by Belt Technologies typically consist of either a sprocket ball bearing tooth design or a pocketed design in the pulley face. Either design approach ensures accurate and repeatable positioning of the steel belt within 0.001”.

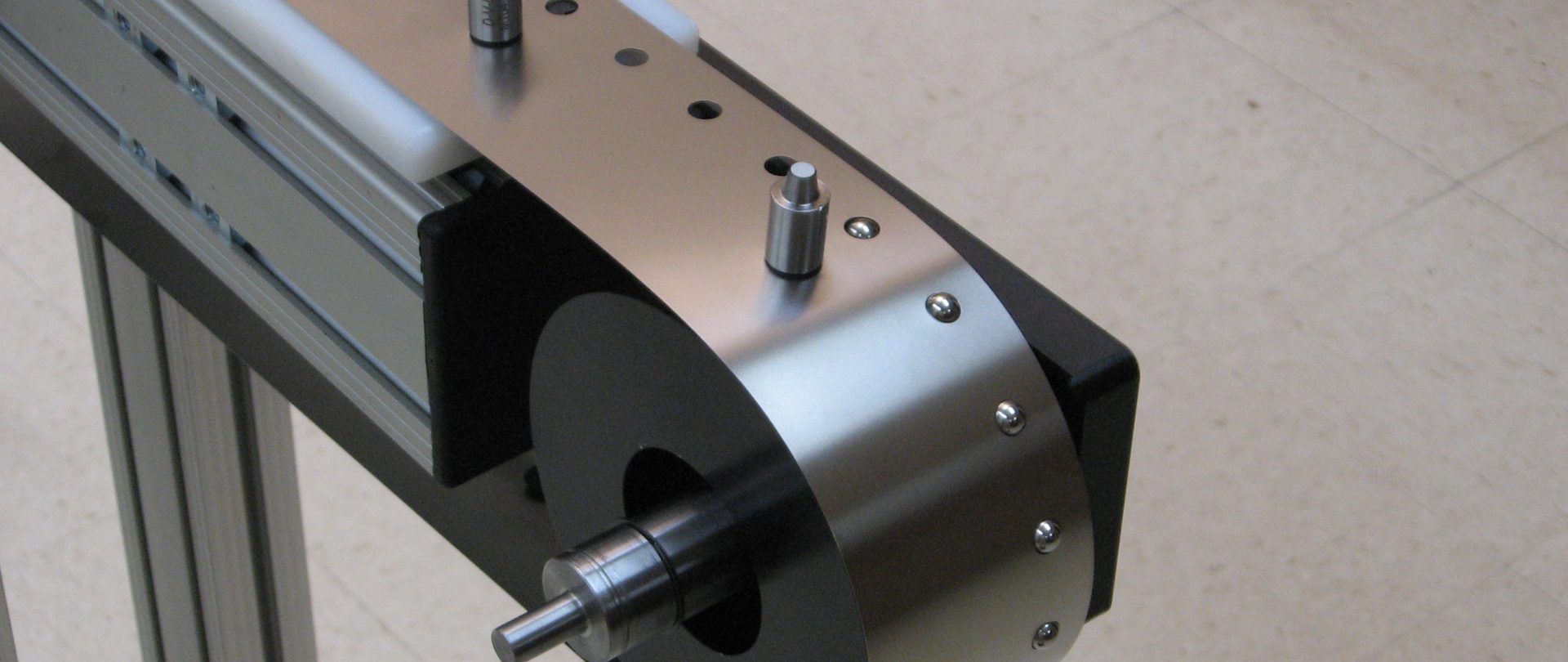

Patented Sprocket Ball Bearing Tooth Design

The sprocket ball bearing tooth design is a patented product by Belt Technologies. This design press fits standard ball bearings into the face of the metal timing pulley to ensure exact engagement with the hole in the steel belt.

The ball bearing design leverages the hardness of the ball bearings for precision and wear resistance, while the spherical design ensures smooth engagement and disengagement of the steel belt. The depth of the press fit controls the clearance between the ball bearing and the hole in the belt. The clearance will result in system backlash of 0.006” to 0.008” if the belt motion is reversed. This clearance can be reduced for specific applications.

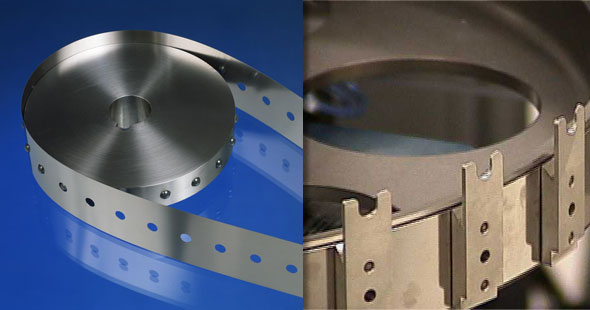

The pocketed timing pulley design is another approach to ensure the steel belt is accurately positioned in the automation system. This approach has pockets positioned accurately in the face of the pulley that engage with a spherical attachment on the belt’s inner circumference.

The spherical attachment can be riveted, threaded or welded to the belt. Clearances between the pocket and spherical attachment typically range from 0.010” to 0.014”. This will result in backlash if the motion is reversed. This timing approach is typically used when tooling is affixed to the outer diameter of the steel belt.

Precise Engagement

Regardless of the type of timing deployed in the system, pulley diameter is a crucial factor for correct operation and extending belt life. For proper engagement of the steel belt, the pulley diameter has to be compensated for the thickness of the steel belt. The Belt Technologies Design Guide explains how to calculate the pulley diameter to ensure precise engagement.

Another factor related to pulley diameter is the bending stress on the steel belt. This is one of the factors that affects how many cycles the belt will operate before fatigue failure occurs. Belt Technologies designs around a 625:1 pulley diameter to belt thickness ratio to maintain bending stress to 1/3 of the material’s tensile strength. This ratio can be violated, but the consequence is lower belt life.

The sales and application engineering staff at Belt Technologies have the knowledge and experience to recommend and design the optimum timing pulleys to ensure proper operation of the steel belt.

Contact us today to discuss your requirements.

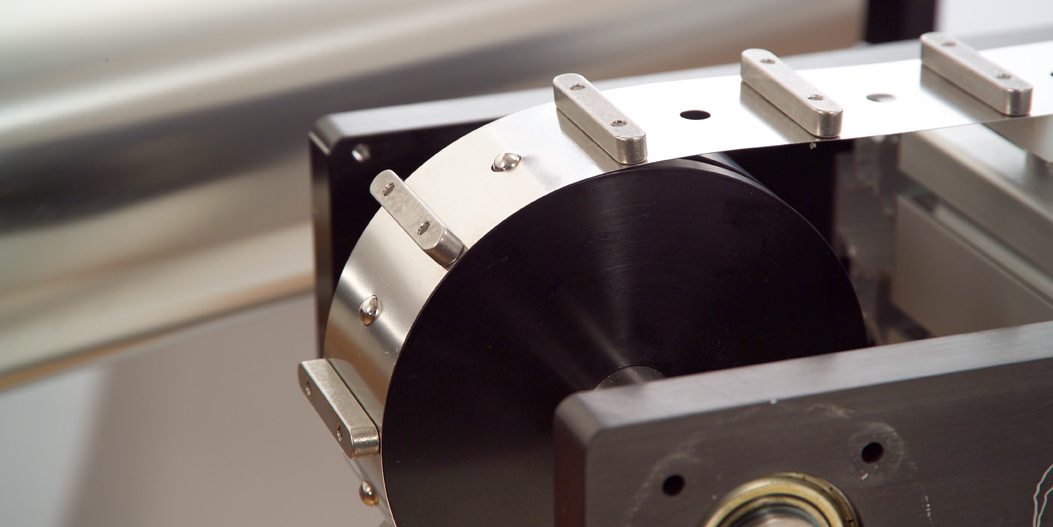

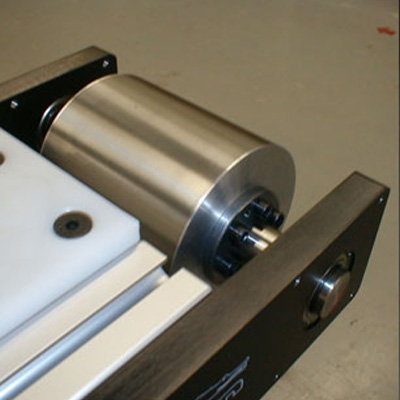

Belt Technologies has developed the TruTension™ tension indicator pulley, an innovative product unique to the belt conveyor market that precisely measures belt tension on conveyor systems.

The TruTension™ Pulley is a complete assembly for simplified installation into your conveyor system. The operation consists of a pulley rotating about a dead shaft through two radial bearings. Tension sensors are incorporated into each end of the assembly, which monitor belt tension on a display through a transducer mounted on one end of the shaft. This system allows continuous monitoring of belt tension for critical applications.

Users will no longer need to build separate systems to measure steel belt tension or find that a belt was destroyed from over tensioning. With the TruTension™ Pulley, a direct readout of tension information is available continuously. TruTension™ Pulleys are also manufactured in the United States of America.

Contact Us

Interested in using the TruTension™ Pulley in your belt conveyor system? Reach out to our experienced team today or request a quote.

Applications

The TruTension™ Pulley has applications in all industries and is compatible with any conveyor.

Engineering Specifications

The specifications for the TruTension™ Pulley are as follows:

| Minimum | Maximum | |

| Pulley Diameter | 2 inches | 24 inches |

| Pulley Width | 6 inches | 36 inches |

| Speed | 1000 RPM | |

| Tension | 12 lbs | 800 lbs |

Explore our PureSteel® Pulleys:

TruPace™ Pulley

See TruPace™ Pulleys

TruTrack™ Pulley

See TruTrack™ Pulley

Friction Drive Pulley

See Friction Drive Pulley