Belt Technologies offers in-house capabilities to meet the unique demands of applications requiring precision, durability and reliability. From extreme temperature tolerance to smooth motion control, our metal belts and conveyor systems are engineered for peak performance in the most challenging environments.

Web Conveying

Belt Technologies offers a range of options for and solutions to automated production for conveying webbed materials and webbed films. PureSteel® belts deliver the high accuracy of lateral motion and direction of travel that are often a prerequisite for such work.

We offer belts with close to zero camber and high accuracies for:

- Printing applications

- Cutting

- Pick and place operations

Auto Tracking

Our tracking solutions, including the Independently Steerable Pulley, provide reliable motion, precise indexing and extended lifespan while minimizing downtime in automated assembly systems.

Automated Casting, Pasting and Sintering Belts

The design and construction of our metal belts make them appropriate for casting operations. The belt thickness is held tightly and our seamless welds ensure surface flatness.

Extreme Temperature

Extreme heat and extreme cold are no match for PureSteel® stainless steel belts and conveyor systems. The tough conditions and range of temperature our belts can withstand—and operate reliably within—have long made us the preferred solution in the food industry.

Why? Neoprene and other belt materials simply cannot withstand such variable temperature conditions without suffering belt damage or distortion.

Our Solutions are Hot, Hot, Hot! (Or Cold!)

We offer several alloys that resist distortion and perform well in applications with elevated temperatures. For instance, Invar will remain flat when operating in environments up to 400°F, compared to 300 series stainless steel which can start to see distortion at temperatures below 400°F. This makes our offerings the perfect solution in ovens or freezers. What’s more, Inconel 625 and 718 can operate in environments with temperatures up to 1,600°F.

Precise/Smooth Motion

When working in extreme environments, with a complex product or with small, fragile parts, you require precise/smooth motion. Our metal belts and conveyor system afford customers:

- Smooth movement

- Precise motion

- Positional accuracy

Design Considerations

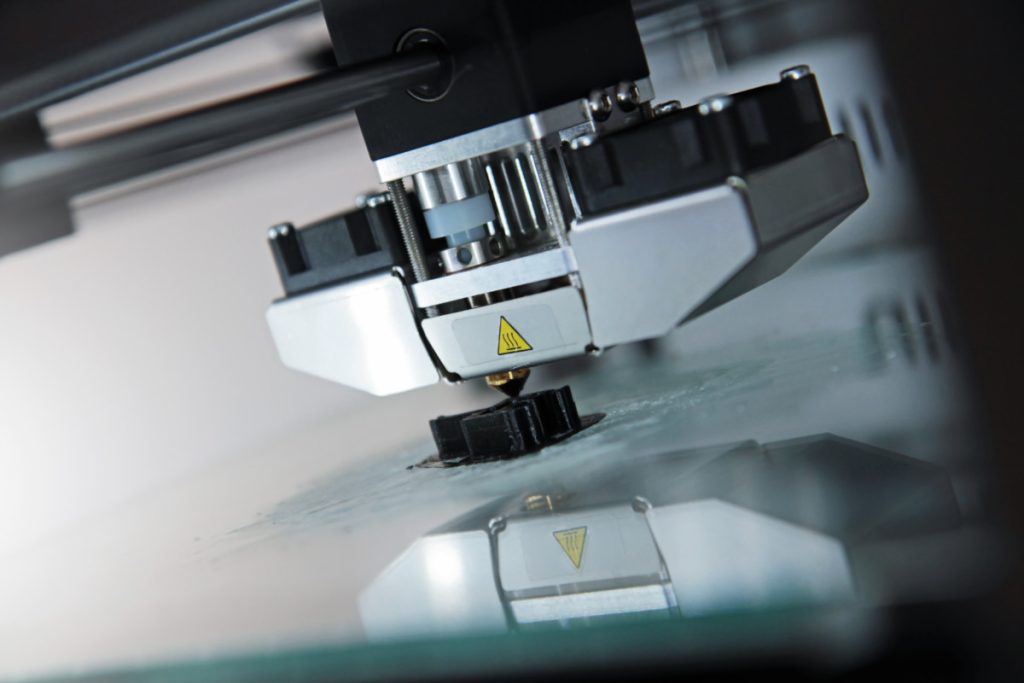

Several design elements contribute to smooth and precise motion control. Motor and gearbox sizing and coupling/bearing choices are important with all belt types. We take all of these factors into account in our fabrication process.

The major advantage with a metal belt is the fact that they’re manufactured using spring steel with a high modulus of elasticity which minimizes the chordal action often seen in other belt types or chain.

This makes them a solid choice in printing, including 3D printers.

Zero Backlash

Belt Technology capabilities include unique steel belt designs which will guarantee zero slip and absolute precision, particularly to robot builders and robotics applications.

Backlash occurs due to clearance between the timing hole in the belt and the pulley’s timing pin. Some clearance is generally needed to avoid interference and let the pins fit into holes, but it can cause backlash when the belt is reversed. When the belt reverses direction, the clearance between pin and hole also reverses, resulting in backlash. This backlash can inject positional inaccuracies into the motion profile. Precision metal belts can be designed to eliminate this. For example, some robotic arms have two steel belts working in tandem with one belt driving the reversing motion. Thanks to the high modulus of elasticity of the steel belt, this design can handle rapid acceleration in both directions without causing backlash.

Our unique steel belt designs can be precision-tailored to the smallest space and harshest environment, allowing development of application solutions in many fields. Running in pairs or with inventive design ideas, these zero backlash drives can be used anywhere tight tolerances exist for back and forth placement.

Antistatic

When it comes to static electricity, the after effects can be anything from a harmless and temporary shock to an employee to damage to components or even to a total disruption to production. Luckily, Belt Technologies offers an antistatic solution: PureSteel® metal belts.

Causes

Because the surface of a belt on a conveyor is continually rubbing against the pulley, friction is present, as is static electricity—unless of course, the belt is composed of stainless steel.

Our Solution for Electronics and More

In industries like robotics and electronics, static electricity can prove detrimental. Luckily, Belt Technologies offers a no-static solution: PureSteel® metal belts. In short, there is no static build up with our metal belts. In fact, metal belts discharge static electricity which can be a critical factor in electronics manufacturing.

Surface Coatings and Textures

Friction

Belt Technologies offers a variety of belt coatings, surface coatings and textures, and surface treatment types on our PureSteel® metal belts to achieve desired outcomes for different applications. If you require a solution with increased friction to the conveyor belt, or one that’s UV resistant, a silicone coating is an option to consider.

We also offer partial etched surfaces. This keeps products in place without compromising the surface release.

The benefits of our surface treatments include:

- Improved lubricity

- Increased friction

- Compressibility

No Sticking

For industries like food processing, where a non-stick surface is required, Teflon® coatings are available. This reduces the friction coefficient or release properties of the surface without compromising performance. We also offer polyurethane coatings if additional friction is required. All of our offered surface treatments and coatings work in tandem with our conveyor systems.

Turn Up the Heat

Consider adding a coating on a heat sealing band for optimized performance. Teflon® coating is an excellent option for increasing the release properties and durability of heat sealing bands.

High-Precision Welding for Stainless Steel Conveyor Belts

Our Proprietary Welding Method Creates Strong, Reliable Welds

Endless metal conveyor belts are made from single sheets of high-quality stainless steel. To create smooth, endless belts and, therefore, continuous surfaces, our engineers utilize proprietary welding methods that incorporate laser, electron beam or plasma welding techniques. Our experienced staff of engineers determine the appropriate welding method based on material and application requirements.

Our welds are high-strength and are able to withstand extreme temperatures, mechanical impact and vacuum conditions without warping or breaking. Our PureSteel® endless steel conveyor belts are used for virtually any application imaginable, in fields as diverse as aerospace, robotics, food processing, medical, industrial automation, semiconductors and more.

High-energy Beam Welding Services

To create a smooth endless conveyor belt, the weld connecting the two ends of the stainless steel sheet must be highly resilient as well as perfectly smooth. At Belt Technologies, we utilize a proprietary welding method to create a strong, smooth weld. Our welders are specially trained in welding sheets of stainless steel to create smooth, endless conveyor belts. Weld-finishing techniques are applied to the joint for better blending, creating an even surface for optimal product handling.

A Smooth Conveyor Belt Surface is Ideal for Impressionable Products

Our solid metal conveyor belts are guaranteed to have flat, even surfaces, which are ideal for applications that need smooth product finishes. The continuous surfaces of our metal conveyor belts ensure that there are no impressions or unsightly markings left on impressionable products such as foods or extruded plastics. They are also ideal for applications that require a high level of precision, like printing.

Special Surface Flatness

Achieve Precise Flatness Tolerance

Our PureSteel® metal belts are able to be fabricated with a smooth surface area with extreme accuracy. It’s this perfect flatness, precise flatness tolerance and the smooth movement our metal belts provide that make our products highly desirable in material handling technology. Assembly or manufacturing lines in an operating environment that require indexing, positioning, or processing equipment are ideal candidates for our manufactured surfaces. In addition, our metal belts maintain their operational flatness, even when exposed to extreme temperatures—hot or cold.

Industries that Benefit from Metal Belt Surface Flatness

The dimensional tolerance and degree of flatness of our belts benefit industries where smooth, reliable movements are required. For instance:

- The production of electronic equipment: We are able to achieve a belt surface flatness of < 0.007” to meet requirements for an electronics customer allowing them to cast ceramic material onto the belt surface for the production of capacitors.

- The printing industry: In printing, positional accuracy (lateral and in direction of drive) is just as critical as belt flatness. For inkjet printing, the ink droplets must be placed to within ten microns in the x, y, and z positions to avoid distortion of the printed image. Our clients can call upon us to achieve this accuracy, helping to positively affect product output—and their bottom lines.

- Food processing: A differentiating factor of our company is our ability to blend the surface area of the belt at the weld. Our finishing process allows us to meet customers’ flatness and surface finish characteristics. This is a special concern for clients in the food industry to achieve product consistency from an aesthetic point of view.

Field Termination

PureSteel® endless stainless steel belts work in most every application and industry. However, we understand that certain machines or applications prohibit their use. To overcome this obstacle, we offer a number of options capable of terminating the belt on the machine.

Overlap Termination

The first option is an overlap termination. The belt ends are overlapped and fastened together using rivets or screws, and the tape is terminated.

Piano Hinge

Piano hinges also create a termination point. We’ll supply the belt with a welded continuous hinge on each end that can be terminated on site by pinning the ends together.

On-Site Welding

Belt Technologies offers on-site welding services. We’ll travel to your location with our custom tooling and weld the belt endless on your machine. Please consult your design engineer to see if one of these options will work for your application.

Tracking Solutions

We can help with the standard steel belt conveyor design to optimize tracking solutions of your PureSteel® metal belt or conveyor system. Belt can also help with engineered forced tracking solutions such as Metrak©, Flanges or Cam followers. For more complex systems, Belt Technologies offers a custom-designed auto tracking system for ease of operator use.

Auto Tracking

Belt Technologies has developed a simple and effective pulley system for independently steering flat belts while allowing for easy, on-the-fly tracking adjustments.

This patented system solves tracking problems that result from changes in an operating environment; it also eliminates downtime by allowing independent belt adjustments on a common, multi-pulley shaft. Steering is accomplished by adjusting the angle of the pulley relative to the belt and modifying lateral tension. Rather than moving the pulley shaft through the use of pillow block adjustments, the ISP design fits a variable steering collar (with either a skewed or offset bore) and a sealed bearing assembly to the body of the pulley. When rotated, the collar changes the angle of the pulley body, resulting in the controlled bidirectional movement of the belt across the pulley face.

TruTrack™ Pulley System

The TruTrack™ Pulley system is another simple and effective auto-tracking solution that monitors and regulates the tracking of a metal belt. It incorporates a frictionless, segmented roller design with edge guides that substantially reduces side loads on the belt, prevents damage to its edge and improves the overall lifespan of the system. The versatile TruTrack™ can be used in multiple industries and applications and comes as a standalone product or as part of a conveyor system designed by our engineers.

Manual Tracking

Belt offers three types of manual tracking:

Pulley Axis Adjustment

Adjusting the pulley axis in a metal belt system is the most effective way of tracking a metal belt. Belt edge tensions are changed in a controlled manner, thus steering the belt. The technique is also applicable to both flat-faced and crowned pulleys. Ideally, both the drive and idler pulleys would have adjustable axes. In reality, however, the idler is the only adjustable pulley. The drive pulley is usually difficult to adjust due to its interface with motors or other power transmission devices.

Crowing Friction Drive Pulleys

When crowned friction drive pulleys must be used, it is in conjunction with—not in place of—axis adjustment. This is because crowned pulleys will not self-center a metal belt. Crowned pulleys work best on thin belts, as the belt web must conform to the crowned face of the pulley. While increased tension can be used to achieve belt-to-pulley face conformity, tension cannot be so high as to cause permanent belt deformation. The optimal geometry for a crowned friction drive pulley is a full radius, with a chord height no greater than the thickness of the belt that is running on the pulley.

Forced Tracking

We often refer to forced tracking as a method for maintaining lateral positioning of a steel belt. In this video, Belt Technologies President Al Wosky demonstrates the use of cam followers as a method of forced tracking. The steel belt edge rides on the bearings’ surface, or cam follower, to achieve belt tracking and lateral position. This method of tracking can achieve an accuracy of better than 0.001 of an inch!

In cases where simple axis adjustment cannot completely eliminate improper tracking, forced tracking methods such as cam followers or glass-filled Teflon® flanges may be necessary and acceptable. System design relationships may need to change; this may involve the use of a thicker belt than might otherwise be recommended, since forced tracking techniques can contribute to a decrease in expected belt life.

Metrak© Tracking

An alternative forced tracking technique for wider belts employs a V-belt bonded to the inner circumference of the metal belt. This two-element belt, which Belt Technologies calls the Metrak© System, distributes tracking stresses on the V-belt rather than on the metal belt, thus maximizing belt life in a forced tracking system.

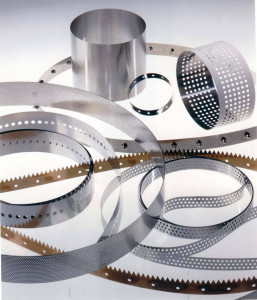

Unique Belt Width & Thickness Combinations

Sometimes the word “custom” means upcharges or a long lead time before you’ll ever see the part you need to get your production up and running. Not so with us. Everything about us is custom and we’ve perfected the engineering of our PureSteel® custom belts so when we say we offer unique belt width & thickness combinations we mean it. It’s this application diversity that sets us apart, and the reason we’re the belt behind diverse product processing. Will our endless metal belts help your specialized project?

Our Offerings

We manufacture PureSteel® belts ranging in width from 0.040” up to 35” wide and thicknesses of 0.001” up to 0.035” thick. Everything we manufacture is custom, so we have the ability to manufacture a specific width and thickness combination based on the requirements of the application.

Everything we manufacture is custom, which also includes coatings, attachments and perforation patterns. Tell us what you need, and we’ll be happy to deliver it. We work with all different industries and design specific widths or thicknesses of customized turnkey solutions for businesses within each. Hear how we helped a zip-tie manufacturer, or contact us with your technical requirements or to discuss your automated manufacturing process and we’ll design a product for your unique application.